FFU Service

A big research institution for Micro- and Nano-technologies in Nordrhein Westfalen enlarges their cleanroom capacity this summer. The additional cleanroom surface is covered by FFU's from NICOTRA||Gebhardt that are controlled and monitored by an existing FFU-control centre since last Tuesday.

The commissioning runs without any problem, besides to the correct addressing only some max-speeds needs to be set by hand, what is really no issue with our control devices for EC-fans.

2019-08-15

Category:

General

Date:

2019-08-15

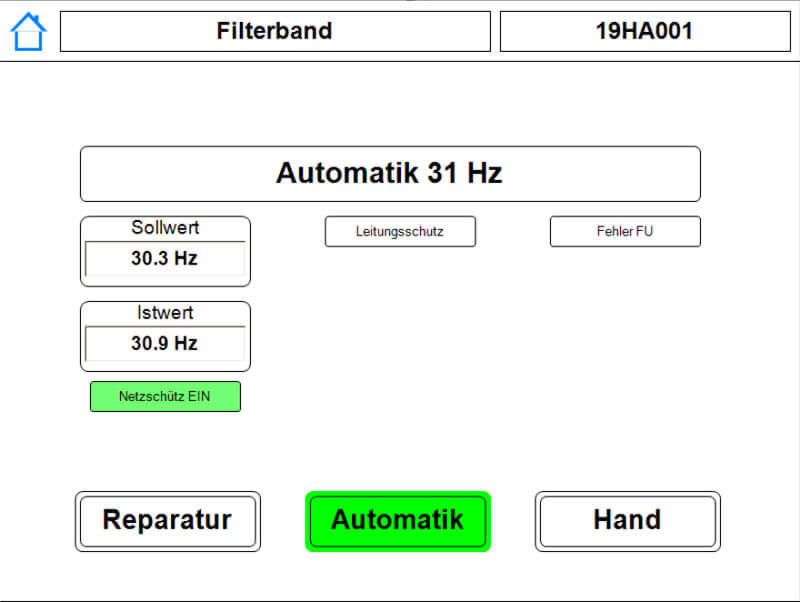

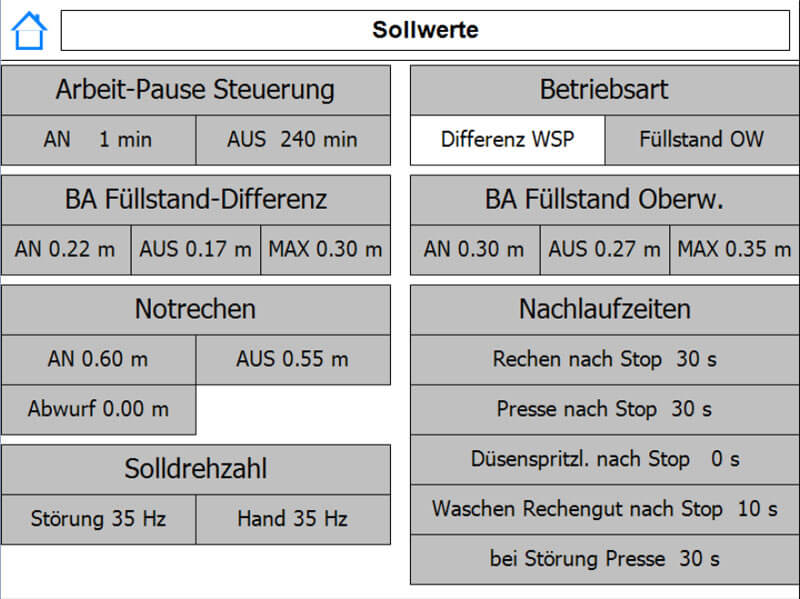

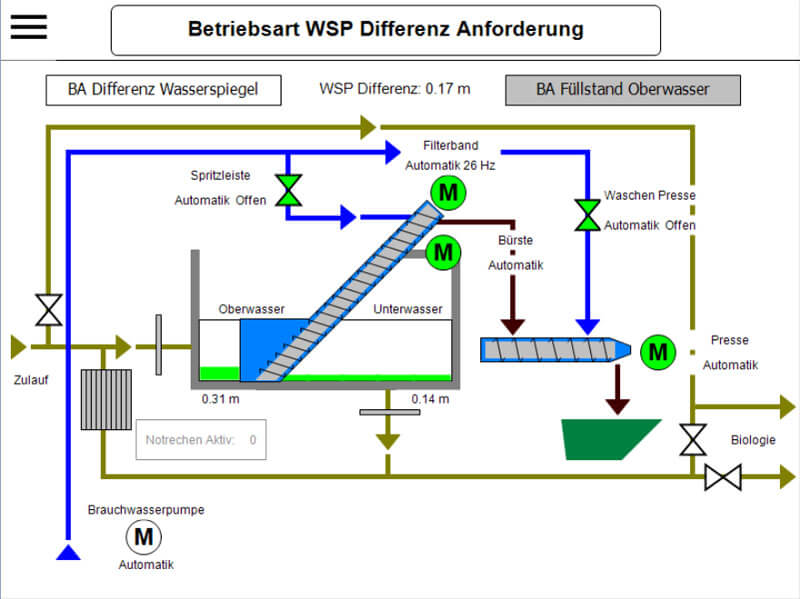

Data link to Beckhoff-PLC via OPC-UA

Our local water supply company is realising a new waste water handling appliance in a small town. The control of the rake bare is our task inside the complex structure.

Two different operation modes are possible; either the difference of water level in front and rear the rake or the level of waste water in front of the rake is used to control. The drive of the rake is controlled by frequency inverter. The measurement of the filling level is realised by 2 radar sensors.

There is a Beckhoff-PLC used as industrial PC with 12’’ touchscreen. The I/Os are integrated by Ethercat, the link to the FMS is done via OPC-UA. All this is programmed by TWINCat3.

2019-07-25

Category:

PLC / automation

Date:

2019-07-25

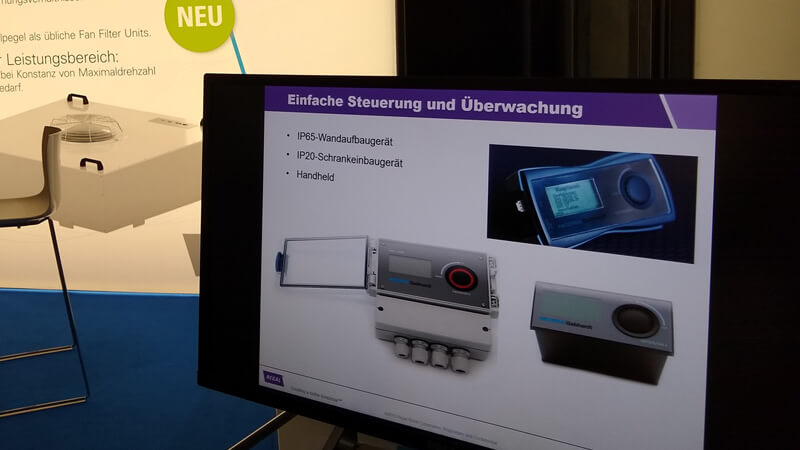

Lounges 2019 - Cleanroomtradeshow

As every year we followed the invitation of an OEM costumer for our fan control devices to visit him at the cleanroom lounge in Karlsruhe.

There we did a lot of interesting talks about the control of fans increasingly under the aspect of IoT.

Booth NICOTRA Gebhardt (Regal Beloit)

2019-02-08

Category:

General

Date:

2019-02-08

Handheld to control and parametrize EC-fans

On of the leading HVAC distributors and contractors in Israel uses, by its own account, mainly EC-fans from ebmpapst and Ziehl Abegg for his appliances.

From now he will program and control it's EC-fans with Modbus- Interface by technologies out of the Vogtland. With that the handhelds of the unqiuom series will be used at 24 countries worldwide.

2018-12-11

Category:

General

Date:

2018-12-11

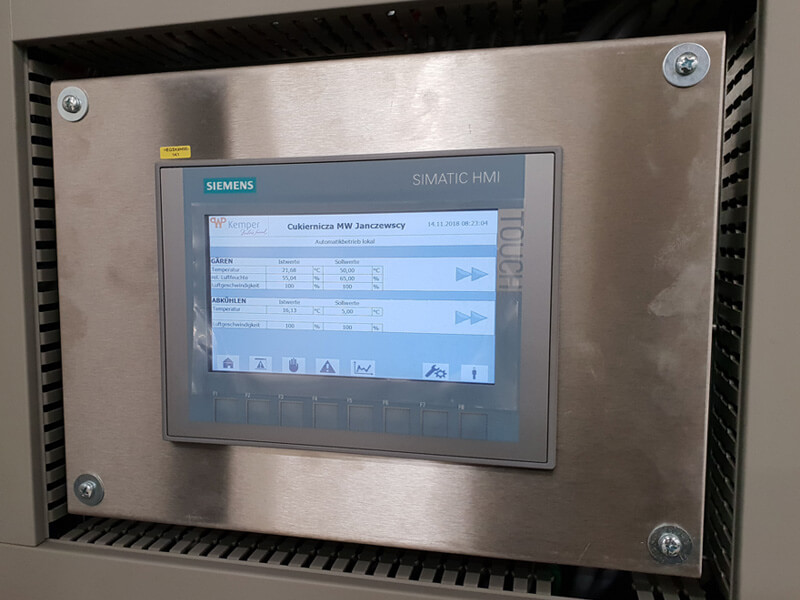

Control and Visualisation of Air Conditioning at SIEMENS SPS S7

Right in time for the Christmas Business and ordered by a big bakery supplier the control and the suitable visualisation of the Air Conditioning of a donut production line was passed to customer at the gates of Warsaw.

Realised on an S7-1500 programmed with TIA-portal it guarantees the air conditioning of 2 rooms, which could do both, proofing and resting.

2018-11-27

Category:

PLC / automation

Date:

2018-11-27

FFU Service - Fraunhofer Gesellschaft

With its various institutes Fraunhofer Gesellschaft belongs to the greatest Cleanroom Operators in Germany.

Yesterday a production shutdown was planned in a job-side in northern Germany, used by different companies to perform their annual maintenance. So the FFU System, delivered with EC-fans from Nicotra||Gebhardt and commissioned by vbk technology in 2013 was checked was well.

2018-11-07

Category:

General

Date:

2018-11-08