EC-Fans / EC-Motors: Advantages, Function, Relevance and the control of EC-Drives

Here you get to know anything about the advantages and the application of EC-Technology in Cleanrooms as well as other fields of Heating, Ventilation and Air Conditioning (HVAC). We will explain to you in detail the function and the meaning of EC-Fans and EC-Motors and their usage in modern industrial plants. To control and monitor these EC-fans permanently as well as for commissioning- and service tasks we provide our own modern Control devices out of our own production, all "Made in Germany".

Page content on the topic EC-fan / EC-Motor

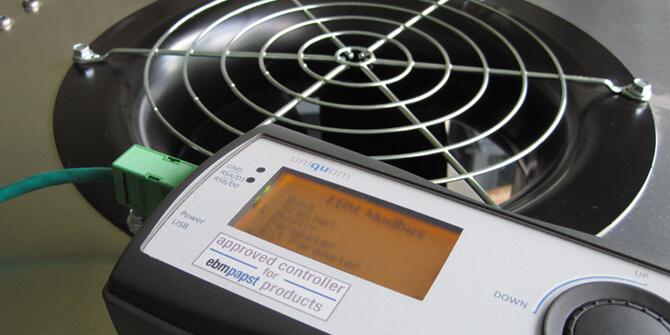

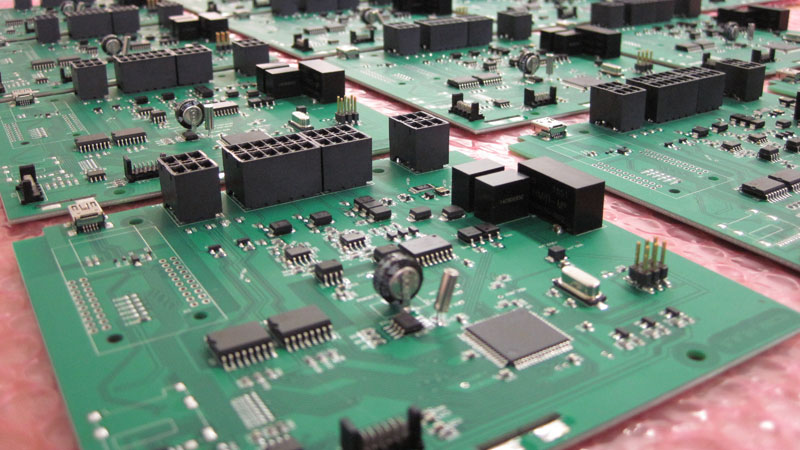

Uniqunet und uniquom high quality and modern control-devices from vbk technology for EC-fans. With only one single device - to start-up and control EC-Drives from different brands. Suitable for EC-fans and EC-motors from different suppliers as ebmpapst, Ziehl Abegg, NicotraGebhardt ( former Gebhardt Ventilatoren ), Rosenberg.

Our Control Devices for EC-fans in the market

95+

customers who apply or resale our control devices

40000+

uniqunet/uniquom - controlled EC-fans in different applications

100%

uniqunet/uniquom - developed, designed and made in Germany

Your contact for topics service, development, programming and and control devices for EC-fans.

born 1974,

skilled Measurement- and Control Technician, 20 years experience in Automation, 2005 Accredited Technician, Designer of FFU-Control-Devices at NICOTRA||Gebhardt

2012 Founder of vbk technology GmbH

born 1969,

skilled Electrician, Study Electrical Engineering main area Electrical Drives, Doctorate 2008, until 2011 R&D Leader of Electrical Drives NICOTRA||Gebhardt

2012 Founder of vbk technology GmbH, Lecturer at the BSW (College of Engineering in Plauen and Chemnitz) and at the Sächsische Kältefachschule in Reichenbach

Advantages

Ec fan advantages

Fans with EC-drives, no matter if from ebmpapst, Ziehl Abegg, Nicotra||Gebhardt or Rosenberg, show highest efficiencies, what means up to 90%.

This leads, especially in partial load range, to a total energy saving up to 50% compared to classical AC drive concepts. Especially in the HVAC applications this is immensely important, where the electronic drives being used very often in partial load operation exclusively.

Special pulse pattern helps to reduce the noise compared to variable-frequency drives (VFD).

Functionality

An EC-drives consists of an EC-Motors where permanent magnets create the required radial magnetic field inside the motor and an EC-controller a sort of frequency inverter that creates the current for the motor in a proper manner.

Especially EC-fans in the HVAC business are integrated that means that motor and controller belong to only one single unit.

Speed Control

The speed control of ec-fans / ec-motors

The speed control of an EC-motor is realized by its commutation control device by its own.

In most cases this drive controller has a standard 230V mains connection, often as a wide range variation, i.e. 208V-277 at 50-60Hz. The user only needs to apply a suitable source for the speed-set-value. This could be a simple analogue signal (0…10V / 4…20mA) as well as a BUS signal that comes from separate control device, as our uniquom - or uniqunet -controllers.

Hence the start/stop command will be set electronically and therewith very smoothly to achieve a very high life-time of the system. On the other hand a switch OFF/ON of the power supply for control reasons is completely unsuitable. It even harms the EC-drive doing it too often.

By using special pulse musters not only the drive efficiency can be increased but also the operation noise of the drive could be limited.

RS485 Bus-systems

A RS-485 BuS-system is physical interface, with drivers and receivers, which are used in serial, asynchronous communication. Typical examples are ebmBUS (ebmpapst) , Modbus (ebmpapst, Ziehl Abegg, Rosenberg, NicotraGebhardt) or the GBus of Nicotra Gebhardt.

Infographic - Advantages EC-fans / EC-motors

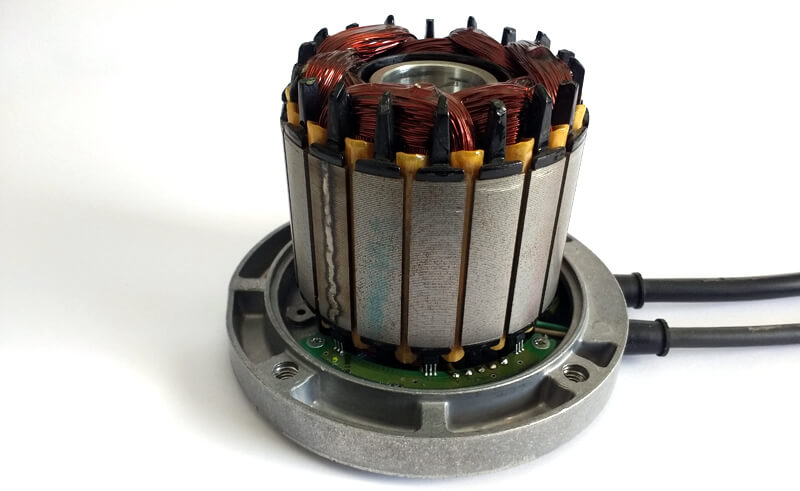

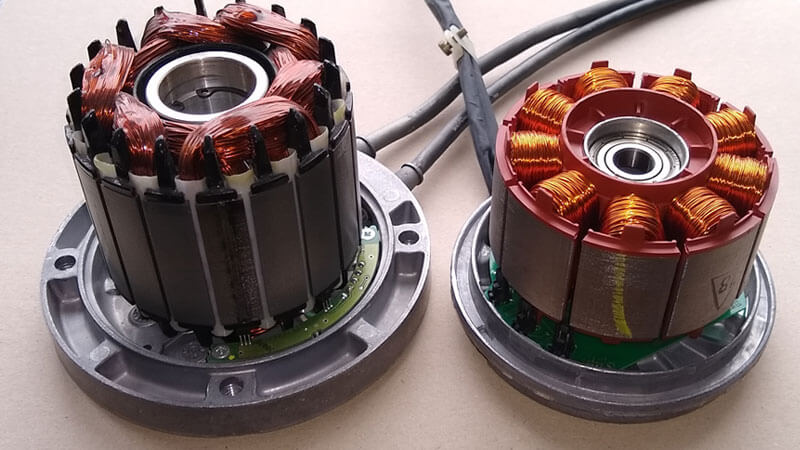

EC motor

Functionality EC motor

EC-motors are according to its name electric commutated motors. The control of the stator winding system is done in accordance to the exact position of the permanent-magnet rotor. The position of the rotor is mainly measured by little hall sensors placed in the EC-motor in rotational sense or is calculated using a special mathematical model. In both variations an electronic drive control of the EC-Motor called EC-controllers is indispensable.

Video - ec motor / ec fan functionality

Stator eines EC-Motors einer FFU - Nicotra||Gebhardt

Rotor eines EC-Motors (ebmpapst) in einer FFU-Anlage

Application for EC fans

EC fans are applied in a wide range of HVAC units, especially in speed controlled systems, where high efficiency and noise reduction matters.

It can be for the control of FFUs or FANWALLs, it can be for Condensers and Evaporators or as classical Exhaust- and Supply Air fans.

FAQ's

vbk technology would appreciate to answer your questions about EC fans or EC Motors. Feel free to contact us . We look forward to your message.

Why are ec fans more efficient?

In every electrical motor a radial magnetic field is required to interact with the motor current to generate a torque. In EC-motors permanent magnets are used for that purpose. Thus there is no additional current required what is effective, mainly in partial load range and leads to highest efficiencies in the whole operation range.

What are ec plug fans?

Fans with backward curved blades are normally higher efficient than those with forward curved blades. They are available either already mounted inside a special housing or delivered without to be plugged by costumer directly in his plant. This is where the name plug fan comes from.

How ec fans work?

EC-fans are designed for the use of a modern

How to control ec motor?

EC-Motors require a matching drive controller compellingly that generates the supply voltage for the EC-Motor. Together they built the EC-drive. Start-Stopp sequences of the drive will be made very gentle what causes higher lifespan for the EC-motor. To the customer the application is very easy, either it is been speed controlled by an analogue 0-10V signal or nowadays by RS485 interface. The latter one can be very easy controlled by suitable control devices i.e. from our house .

How ec motor works?

The function of an EC-motor is quite simple as the switching from (winding) phase to phase is not made by a mechanical commutator but by the drive controller, that’s why it is called Electronic Commutated. The exact rotor position is normally been detected by tiny little hall sensors placed inside the motor.

What is a FFU / Fan Filter Unit?

Air Filtering Equipment with Fan, taking Air from the ceiling pressing it through the filter into the cleanroom, either as laminar or turbulent flow. Control of the FFU either by a FFU-Control Center or directly in closed loop manner for a required volume, pressure, speed or any other control value.

How a brushless DC-Motor works?

Brushless Motors or Brushless-DC-Motor is just a different term for EC-Motors. Controlled like an DC-Motor, they don’t have either carbon brushes or commutators, what leads to a very low level of wear. While the term "EC-Motors" has been used mainly by ebmpapst to promote their high efficient drives, i.e. NICOTRA Gebhardt calls theirs products "Brushless DC-Motors" officially.

To drive a Brushless DC Motor a drive controller is needed mandatory. This drive controller can be either mounted inside the housing of the Brushless DC Motor or realised as an external stand-alone unit. The commutation of the drive controller can be made based on hall sensor or sensor-less as well.

Service

Development

For our customers we design different diagnostic and control devices for EC-drive market. This includes drive controllers incl. COM-interfaces (analogue, Modbus rtu as well as other, even proprietary, RS485 systems).

Furthermore we plan whole concepts for electric drives (asynchronous and synchronous) especially for fans as well as special applications.

Service

We help our customer at the design, the data management and the project programming of FFU appliances. Furthermore we would like to support you while the commissioning of new cleanroom appliances or extensions and perform on demand an error diagnostic with our own designed tools (i.e. uniquom / uniqunet ) including a final troubleshooting.

Our Projects - EC Technology

FFU-Control ebmpapst Modbus 5.0.1 lite

Normally the commissioning of “smaller” cleanrooms with our EC-control devices runs smoothly, that even completely new customers are able to manage this with a bit telephone support no matter if the FFUs uses ebmpapst-, NicotraGebhardt-, Rosenberg- or Ziehl Abegg-drives. But not so at a Biotec enduser in northern Germany end of January. Unfortunately more than one single issue existed that causes some trouble. Firstly a wrong cable PIN of the RJ45 (green/white instead of orange/white) was used that NetA and NetB of the main backbone was no more a twisted pair. Furthermore due to whatever reason the Modbus communication was not that fast and swift as usual.

As beside of a very few revisions hatches the whole cleanroom was completely sealed the search for the root cause for the pretty sluggish communication was not found. Finally a proper termination (RT = 120 Ohm) at the end of the modbus-rtu-line of 400m length lead to better system response times that the customer was satisfied even if the technicians loves to understand such things completely.

Maintenance of a FFU Plant

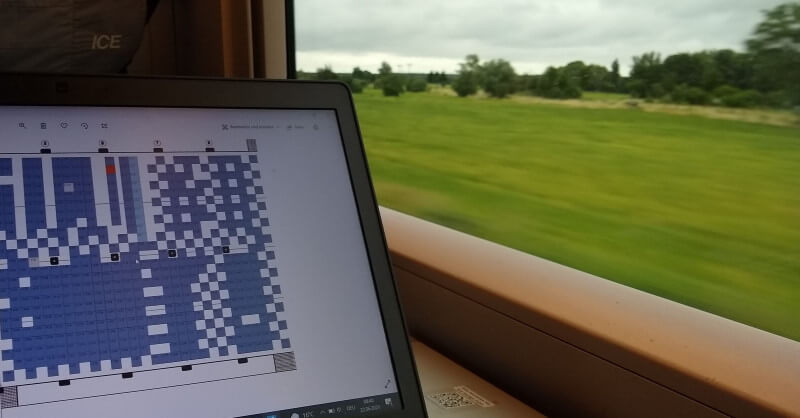

To avoid unpleasant surprises at the maintenance on site, a careful log-data analysis in detail is obligatory in front of the maintenance trip . This is on one hand highly professional towards the costumer and helps on the other side to prepare the trip properly. If no heavy tools and spare parts are required, the climate friendly train trip is always 1st choice.

Since 3 years the FFU-plant with EC-fans from Nicotra||Gebhardt is running free of trouble. To avoid occasional communication errors in the Ethernet / Modbus-rtu Network, the Gateways and the LON-Remote-Network-Interface (RNI) were updated with the latest firmware.

Modbus/TCP - FFUs from 2 Decades driven by a single Central Control Unit

Most of the German automation companies are established giants using and extending their cleanrooms since more than 2 decades. Consequently the FFU-Control-Servers bases on very different generations of Hard- and Software. One of these companies, who at least used FFUs of different generations all with RS485 field bus systems, we supported now to adapt all FFUs of all these generations to his one and only Facility Management System (FMS).

From now one his gateways communicate “upwards” via Modbus-TCP with his FMS and “downwards” with the respective field-bus system. The different bus-systems are selectable via Gateway WEB-GUI in a very simple manner the control itself is done automatically. Our customer was delighted as he took a video of the commissioning with 4 different FFU-types with 20 years in between there manufacturing date.

EC Motors – often without Temperature Sensors inside

Also this year your author supports the Sächsische Kältefachschule at their education in different graduation levels. The chosen topics content again electrical drives mainly EC-drives.

A constantly recurring question is, why do so many EC-motors do not have any temperature sensor inside as – no matter if a simple clixon-contact, a PTC or even a PT100 – most induction motors do have. The answer lies in the functionality in combination with its needed direct combination with a control drive. Sometimes unconscious you consider an application inside an EC-fan. In this combination of EC-motor, Control-Drive and an impeller it succeeds that with a fixed combination of motor with impeller, combined with a simple limitation of running speed the motor can be protected by overheating as long as the medium temperature of the moved air is not improper high.

EC Motor Control – Parameter Variance against Bottlenecks

By the end of the last year a US-American OEM-customer placed a bigger order for controllers for their EC fans. He is going to proceed by controlling their EC-FFUs with our EC-control devices. The biggest possible variety of different data sets for all EC-fan suppliers (ebm papst, Nicotra Gebhardt, Ziehl Abegg, Rosenberg) was more than welcomed. Obviously they are preparing themselves to avoid any bottlenecks when it comes to some postponements at different EC-motor manufacturers. We appreciate to support.

Maintenance of a FFU Plant

It speaks for the process equipment if you do not take note about it. After almost 10 years trouble free operation of a FFU-plant with EC-fans from Nicotra||Gebhardt the owner decided to let someone check whether if anything is fine or not. As the FFU Server is not linked to the Internet and the whole system including Inline-I/O-station as well as the old OPC-DA link are still in fine operation and no intentions to use some virtual solutions for the FFU-Control exist, we feel confident to state ‘currently no changes recommended, probably a slightly higher maintenance frequency is not a bad idea’.

Almost traditionally trips to the technology hot spot in Jena are scheduled by train. The way home at the lower train way creates unbelievable joy.

Automation of a FFU Plant

In week 41 the commissioning of our largest single 2021-project took place. From now on a FFU-Server including 4 structural layers is controlling up to 2.000 FFUs. Therewith our design- und programming efforts have been concluded worthy. Due to the size of the plant and its geometrical distances from the central FFU-Server to the EC-FFUs the communication to the 6 Gateway was realized by individual fibre links. Inside the FFU-Server an OPC-UA Server is integrated. It allows access to all data points, of each FFU individually, group wise or by structures along a customer FSM.

Due to the order volume and for the general importance the order had highest priority. Consequently we accomplished our tasks on the Server in advance of the commissioning close to perfection. Therewith we had enough time to support the customer by the communication checks and address-building works on site. Therefor once more two EC-fan control devices from our house has been used.

Extension of a FFU Control Centre

Recently a great research company in the north of Hamburg enlarged its cleanroom capacities. Therefore FFUs with EC-fans from Nicotra||Gebhardt were purchased that should be integrated to the existing FFU-Control-Centre. The owner purchased this service directly from us. We are delighted about such jobs, as they are normally executable without major tools. Hence the trip can be scheduled climate-friendly and comfortable by train. Rarely more than a control device , to scan the FFU-lines with the ec-drives, and a laptop is required.

At the end there were only winners, the costumer was getting professional first-hand service, Nicotra||Gebhardt appreciates it’s FFU-control-partner, we have been able to do some day-to-day business utterly relaxed at the train trip and not to forget our environment.

Particularities of Brushless-DC Motors – Part II

… recently we reported about Brushless-DC Motors, that worked, driven be the overpressure in a cleanroom, as generators. The charged, along the back-emf diodes of their IGBTs, the DC-link at least partly that the switching power supply and therewith the communication started. As there is no correct charge of the PFC this is an undefined state so the mainly created FF-command sequences interfered the Gateway where the units still were connected to. The Gateways however interpreted this wrong and was brought out of step.

The solution was rather simple, a slight modification of the interrupt routine (IRQ) was done just to block the interrupt at the crucial point. So from now on the Brushless-DC drives can operate as Brushless-DC Generators and talking half asleep to the network without interfering their proper working colleagues.

Particularities of Brushless-DC Motors – Part1

It’s known, that the commissioning of larger projects takes longer and not anything can be expected in advance. One of our big FFU partners experienced this at firsthand. Normally the FFUs with its EC-Motors, that partner calls Brushless-DC Motor, will be mounted, wired and the belonging controllers individually addressed and finally powered-on section wise. Afterward the line will be scanned by a special control tool for those brushless-DC Drives, a possible wrong addressing corrected, followed by a short test run launched by control device whether anything is ok. At the end of this procedure you “get” a line that is addressed correctly and capable to communicate. Finally the line will be set to sleep per Stop-command, and not via power-off, for being ready for higher tasks.

If now, due to what reason ever, most of the FFUs with its Brushless-DC drives run at nominal speed the cleanroom will be set under pressure. Subsequently those fans being simple powered-off start to run in reverse mode. Now the Brushless-DC Drives show their particularities. The Brushless-DC Motor starts to windmill and operates as generator and charges via the reverse diodes the DC-link of the controller as long as the internal power supply and therewith the BUS-communications start to “work” or better to get to half asleep. The sent order sequences are a kind of half correct signal noise that is overlay the normal communication of the FFUs that are running powered-on at normal speed, what we are supposed to filter now. ... to be continued!

Cleanroom catalogue - ebmpapst

Under the headline „Providing clean area hand in hand with well-known manufacturers“ our control devices for EC-fans are shown in the new Cleanroom catalogue from ebmpapst.

The most important point seems to be that there are special parameter sets for each of the relevant BUS systems ( ebmBus, ebmBus/DCI as well as Modbus and Modbus/DCI) what allows a line wise mixed operation of these different fans at one single FFU-Control-Centre. This is especially relevant for plant expansion.

FFU Service for Nicotra||Gebhardt EC fans

The last week before Christmas is normally the scheduled time for a production shutdown at a big cleanroom-site in Jena, where different suppliers and partners use this for their annual maintenance. So the FFU System, delivered with EC-fans from Nicotra||Gebhardt, once commissioned by vbk technology and since that supervised by us, was checked as well. As the FFU-Server has been switched to a virtual platform in 2020, no investigation of the server hardware has been required this time.

Finally a measurement of the pressure-drop of a certain number of EC-FFUs took place. Therefore the existing aerosol-hose network was used, we could dispense to access the cleanroom.

EC-Control Device

The long wait ends right now. Besides to all joy the look at our interactive costumer card triggered some mixed feelings at CEO Mathias PAUL. Still “grey” was our beautiful neighbour country, as a part of the bloodline of his grandfather started in the Steiermark/Austria. But this is now to end. From now on a large player for electronic lengths measurements will control parts of his cleanroom by using control devices for EC-drives made by vbk technology.

The question remains – and our adorable neighbours will forgive us the joke - what are they really going to do with that, believing @realDonaldTrump „They live in the forest“ we have some doubt if it is to control FFUs with EC-fans in cleanrooms whether from Nicotra||Gebhardt, ebmpapst, Ziehl Abegg or Rosenberg. ;-)

Rosenberg Modbus Gen2/3

One of the big cleanroom players in the US planned to use Rosenberg EC-fans for its FFUs for a cleanroom project. So our task was to create a firmware update for our EC-Fan Control device uniqunet to control exactly these fans. As the handling of the reading- and writing-register of the Rosenberg Modbus is kind of tricky it was a bit of a challenge to get this integrated inside the package-commanding structure of the uniqunet control device.

At the end there is besides some compliments from the costumer an appealing hardware order, of course including the new firmware.

At the Green Island – Control Devices for EC-Fans

The Green Island was up to now a black spot at our . This is now to be changed. The biggest distributor of ebmpapst in Ireland requires on of our EC-Control devices a customer.

The handtool of uniquom series should control EC-fans with ebmBUS- and Modbus-Interface, but especially whole parameter sets of Modbus fans should be cloned. Therefore the vbk.cmd Clone Master is the right platform to save whole data sets individually for each project before sending out the ec-fans to customers’ site.

MODBus-RTU-DCI vs. MODBus-RTU

to stay deliverable, on of our cleanroom customers decided somewhat unsuspectingly to apply the DCI-Variation, instead of the normal MODBus-RTU variation of his EC- FFU s from ebmpapst. As consequence some single commands of the "Install fan"- order package of our FFU-control device uniqunet ended in nowhere, that the installation process could not be accomplished. Even if not caused by us a software adaption of the uniqunet control device seemed to be the most simplest solution.

Seven days, incl. basic investigation, program adaption, test, verification and application at customers’ side is more than presentable, as we do think.

Cleanrooms – Modernization of an ebmpapst Control

Following a recommendation by ebmpapst a big building automation company from Leipzig requested support for renewing a FFU control system of EC-FFUs, each with an ebmpast-drive, in Erfurt.

With pleasure we provided, besides to some advices, a handheld tool for the EX-Fans free of charge to check the operation of the system. As only the terminal-box has been changed to one with ebmBUS interface, it was not entirely clear if a surprise awaited the costumer.

Yesterday evening we received the enjoyable feedback, anything went perfect and that easy that they even had enough time to address the FFUs already correctly. So there are no technical reasons that speak against the usage of 3 EC-FFU Control devices.

EC Motor Control for US-Cleanrooms

By mid of March a US-American OEM-customer placed an order for controllers for their EC fans. Hand programming tools as well as EC Control devices for the fixed installation were ordered to use the ec fan advantages of their ec fan technology in cleanroom applications.

It is for us more than a matter of decency, even in difficult times, to match costumers’ wishes in terms of delivery date. Due to the outstanding commitment of our employees we achieved to create a time reserve the American duty know “to use”.

FFU Commissioning at Bielefeld University

Last Tuesday we realized the final commissioning of an FFU-appliance at the Institute of Experimental Physics at Bielefeld University.

In total 13 FFUs of different sizes, equipped with EC fan technology, show up their advantages. They are separated to 4 groups controlled by 2 different EC-fan control devices from 2 different generations.

Handheld to control and parametrize EC-fans

One of the biggest energy suppliers in the western part of Switzerland is now using technologies out of the Vogtland to parametrize and control his EC-fans from ebmpapst.

The chosen parameter set for the service handheld does not only allow to control EC-Drives with Modbus - und ebmBUS-interface but to clone whole parameter sets within seconds from ec-fans of the same physical size.

Bearing Monitoring for Smoke Extract Fans

Smoke Extract Fans, whether as Radial- or Axial fan, should keep emergency exits and paths free of smoke. Even if there is no normal air ventilation required, a save start and operation is demanded in case of fire to achieve the nominated run time for such a fan. A proper function of the motor bearings is there for indispensable.

The bearing monitor unit that was especially developed for a fan manufacturer evaluates different frequencies out of the swinging acceleration that needs to be measured. The evaluation is more or less independent from the type of fan, motor and bearing and it even detects pre-damages of the ball bearings from the induction motors.

However a little more complex is the monitoring of the bearing conditions at EC-fans, because the measured frequencies overlap with the switching frequencies of the EC-Controllers.

The evaluation is quite easy as a simple traffic light control (green-yellow-red) at the device. A special software can be applied for detailed damage analysis.

FFU Service

A big research institution for Micro- and Nano-technologies in Nordrhein Westfalen enlarges their cleanroom capacity this summer. The additional cleanroom surface is covered by FFU's from NICOTRA||Gebhardt that are controlled and monitored by an existing FFU-control centre since last Tuesday.

The commissioning runs without any problem, besides to the correct addressing only some max-speeds needs to be set by hand, what is really no issue with our control devices for EC-fans.

Handheld to control and parametrize EC-fans

On of the leading HVAC distributors and contractors in Israel uses, by its own account, mainly EC-fans from ebmpapst and Ziehl Abegg for his appliances.

From now he will program and control it's EC-fans with Modbus- Interface by technologies out of the Vogtland. With that the handhelds of the unqiuom series will be used at 24 countries worldwide.

FFU Service - Fraunhofer Gesellschaft

With its various institutes Fraunhofer Gesellschaft belongs to the greatest Cleanroom Operators in Germany.

Yesterday a production shutdown was planned in a job-side in northern Germany, used by different companies to perform their annual maintenance. So the FFU System, delivered with EC-fans from Nicotra||Gebhardt and commissioned by vbk technology in 2013 was checked was well.

Service uniqunet – FFUs in Cleanroomapplication

„Troubleshooting - Commissioning - Training“ were written at the P.O. of a big plant engineering company. They pleased us for support for commissioning a FFU-network with fans from ebmpapst with Modbus Interface at site and to train the operating staff afterwards.

After an address-conflict was eliminated in the FFU-network and no other abnormalities were found we did the programming of the uniqunet FFU-control device together with the end user. Now 3 FFU groups will be controlled according to the manufacturing process with different set-values in day/night mode.

Service uniqunet – FFUs in Cleanroomapplication

Lounges - uniqunet control device supports NICOTRA Gebhardt FFU

After a few years of absence the Cleanroom Lounges took place in Karlsruhe this year again. Personal highlight for me was the operation of a of an uniqunet control device driving an EC-fan of a NICOTRA Gebhardt ( former Gebhardt Ventilatoren ) FFU.

NICOTRA Gebhardt has been an OEM costumer for our control devices for years.

uniqunet control device supports NICOTRA Gebhardt FFU

FFU Service for NICOTRA Gebhardt

A well-known research institute in Munich had scheduled a filter change of their FFU's for the last week. Here, the opportunity was taken to check some communication abnormalities in the control of the FFU's by a FFU-Control-Centre type FanCopmmander200). The installation was commissioned with components from NICOTRA Gebhardt in 2005.

All involved have been delighted as it has been find out that neither the EC-FFUs nor the FanCommander200 has caused the problem but just a simple hidden cable damage in the main backbone. After renewing it, the installation is running perfectly again and that after this long run time.

control devices for fans

uniquom®

A modern hand device to control and to parametrize several devices with RS485 interfaces.

uniquom® - get more information Downloads and information uniquom

Downloads and information uniquom uniqunet

Stand-alone Monitoring and Control device for different applications with RS 485-based interfaces.

uniqunet - get more information Downloads and informationen uniqunet

Downloads and informationen uniqunet