Automation of a Refrigeration System by SIEMENS SPS S7

Around 1900 breweries were often set in the underground a plant of chestnut trees for cooling on top. True or not, this is what came to your author attention while watching a TV-report about Carl von Linde. Today the chestnut groves will be used more often to sit here and enjoy the results of the brewing process, the cooling is business of technique. Last week we had the opportunity to support our partner KälteConcept in doing the whole automation at a refrigeration system.

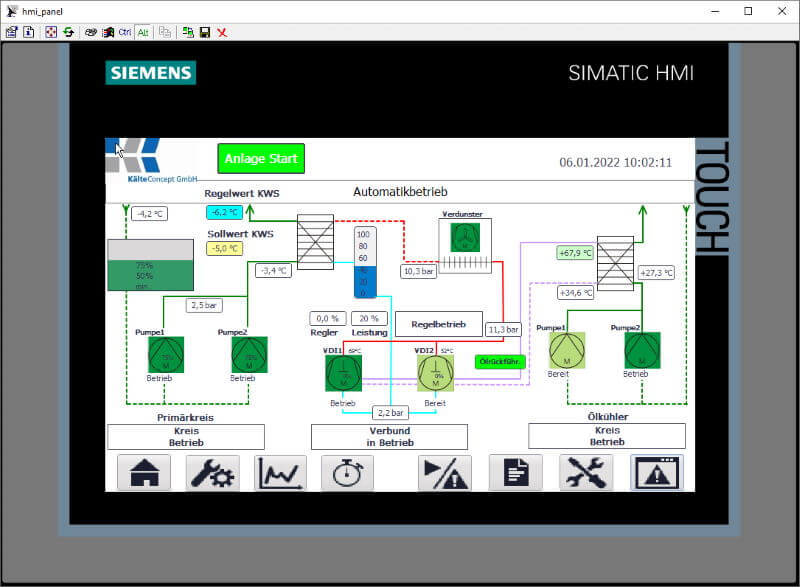

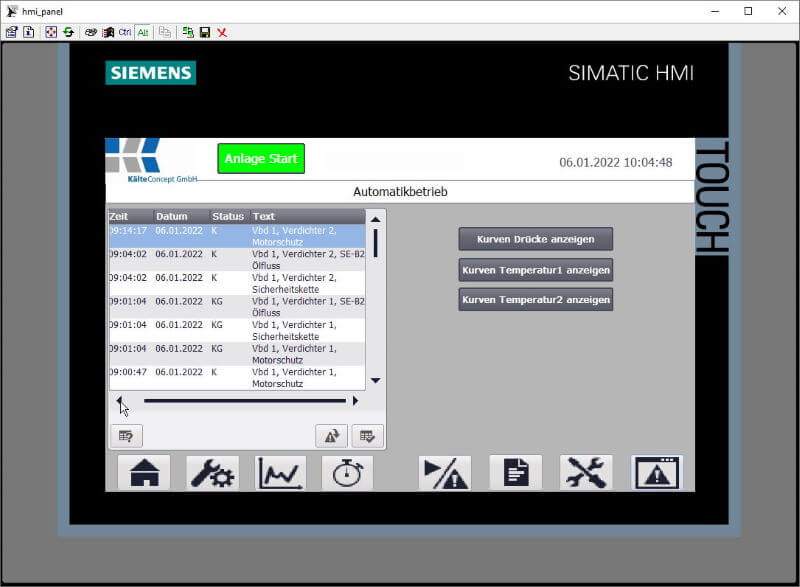

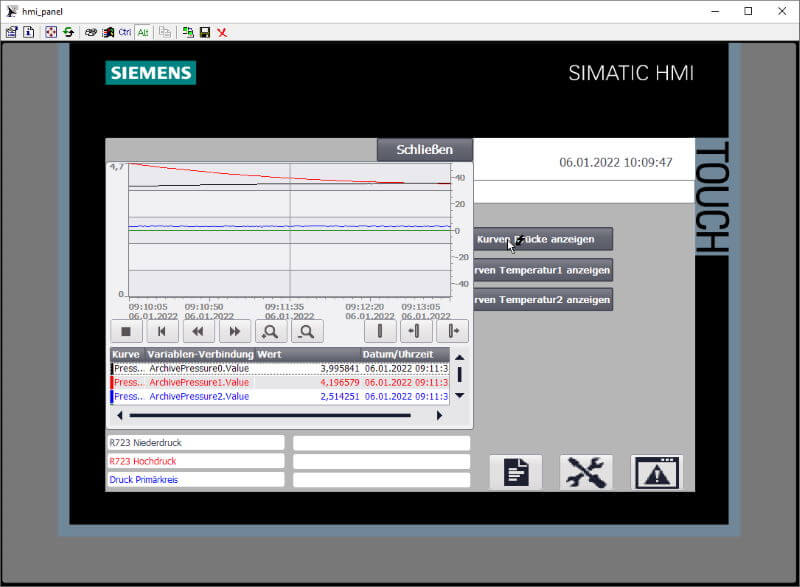

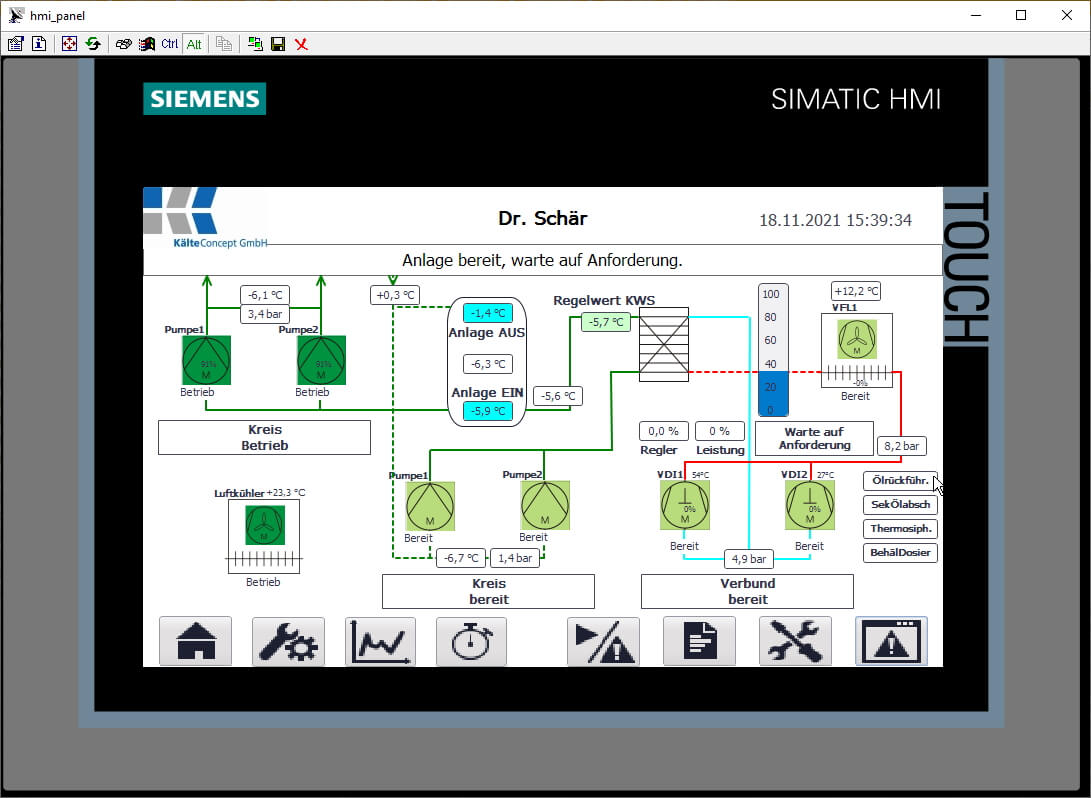

The core was a S7-1500 used as CPU, as HMI a KTP900 comfort is used. The cooling appliance consists of 2 screw compressors from Bitzer. The cold brine cycle was realised with 2 Magna pumps, controlled in close loop by pressure, while the 2 Grundfoss-pumps of the lubrication cycle were controlled alternating in redundancy for sake of a long operation life. The highlight of the automation is an error log, that saves all relevant pressures and temperature carts of the last 3 minutes BEFORE an error will have occurred.

2023-01-12

Category:

PLC / automation

Date:

2023-01-12

Maintenance of a FFU Plant

To avoid unpleasant surprises at the maintenance on site, a careful log-data analysis in detail is obligatory in front of the maintenance trip . This is on one hand highly professional towards the costumer and helps on the other side to prepare the trip properly. If no heavy tools and spare parts are required, the climate friendly train trip is always 1st choice.

Since 3 years the FFU-plant with EC-fans from Nicotra||Gebhardt is running free of trouble. To avoid occasional communication errors in the Ethernet / Modbus-rtu Network, the Gateways and the LON-Remote-Network-Interface (RNI) were updated with the latest firmware.

2022-11-10

Category:

General

Date:

2022-11-10

Modbus/TCP - FFUs from 2 Decades driven by a single Central Control Unit

Most of the German automation companies are established giants using and extending their cleanrooms since more than 2 decades. Consequently the FFU-Control-Servers bases on very different generations of Hard- and Software. One of these companies, who at least used FFUs of different generations all with RS485 field bus systems, we supported now to adapt all FFUs of all these generations to his one and only Facility Management System (FMS).

From now one his gateways communicate “upwards” via Modbus-TCP with his FMS and “downwards” with the respective field-bus system. The different bus-systems are selectable via Gateway WEB-GUI in a very simple manner the control itself is done automatically. Our customer was delighted as he took a video of the commissioning with 4 different FFU-types with 20 years in between there manufacturing date.

2022-05-15

Category:

General

Date:

2022-05-15

EC Motors – often without Temperature Sensors inside

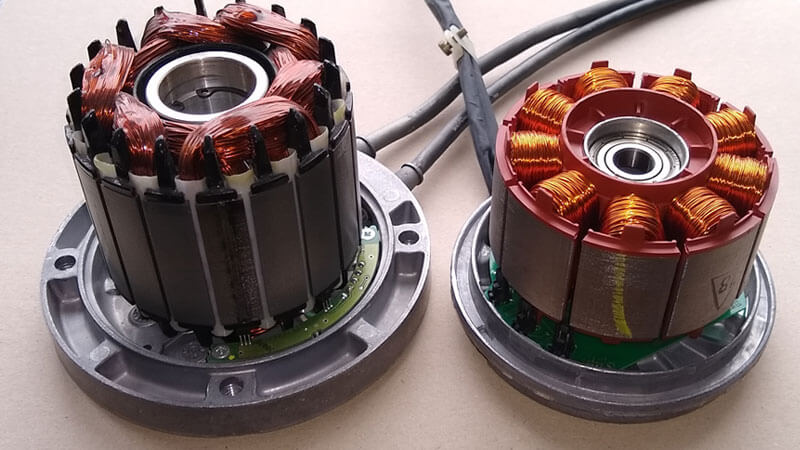

Also this year your author supports the Sächsische Kältefachschule at their education in different graduation levels. The chosen topics content again electrical drives mainly EC-drives.

A constantly recurring question is, why do so many EC-motors do not have any temperature sensor inside as – no matter if a simple clixon-contact, a PTC or even a PT100 – most induction motors do have. The answer lies in the functionality in combination with its needed direct combination with a control drive. Sometimes unconscious you consider an application inside an EC-fan. In this combination of EC-motor, Control-Drive and an impeller it succeeds that with a fixed combination of motor with impeller, combined with a simple limitation of running speed the motor can be protected by overheating as long as the medium temperature of the moved air is not improper high.

2022-04-08

Category:

General

Date:

2022-04-08

EC Motor Control – Parameter Variance against Bottlenecks

By the end of the last year a US-American OEM-customer placed a bigger order for controllers for their EC fans. He is going to proceed by controlling their EC-FFUs with our EC-control devices. The biggest possible variety of different data sets for all EC-fan suppliers (ebm papst, Nicotra Gebhardt, Ziehl Abegg, Rosenberg) was more than welcomed. Obviously they are preparing themselves to avoid any bottlenecks when it comes to some postponements at different EC-motor manufacturers. We appreciate to support.

2022-02-04

Category:

General

Date:

2022-02-04

Control of a Water Chiller by SIEMENS SPS S7

More and more people suffer from intolerances to different ingredients of foods. Consequently mainly large bakeries creates special products and therewith a kind of normality for those people. For one of these larger bakeries we commissioned a NH3 cold water chiller together with our partner KälteConcept at the end of last year.

Of course we applied our proven rack controller for climate cascades. The core of the automation is Siemens S7-1500 using TP900 Comfort Panel as HMI controls 2 large centrifugal compressors of 75kW each. The total Refrigeration power is roundabout 420 kW. The most sophisticated item is the permanent archiving of the important operation values in a ring buffer. So in case of an error all process data of the last 30sec before the error occurred are available. In in case of a failure it makes the service work way easier.

2022-01-15

Category:

PLC / automation

Date:

2022-01-15