PLC Programming / Industrial Automation - Our projects

Cleanroom Automation with Siemens S7-OpenController and ET200

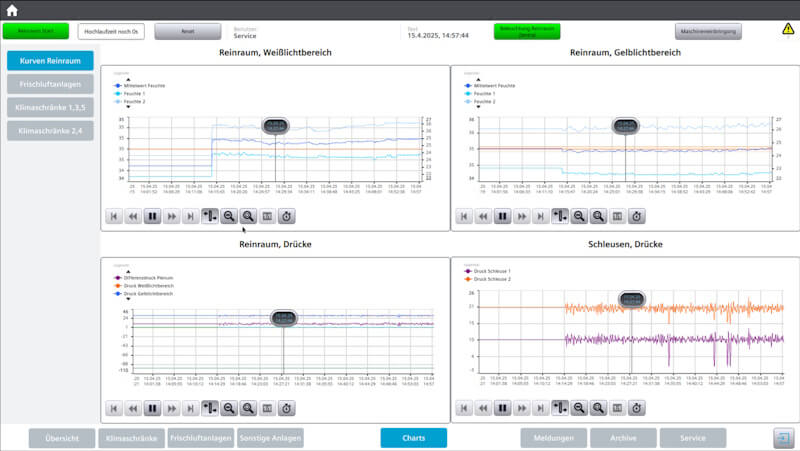

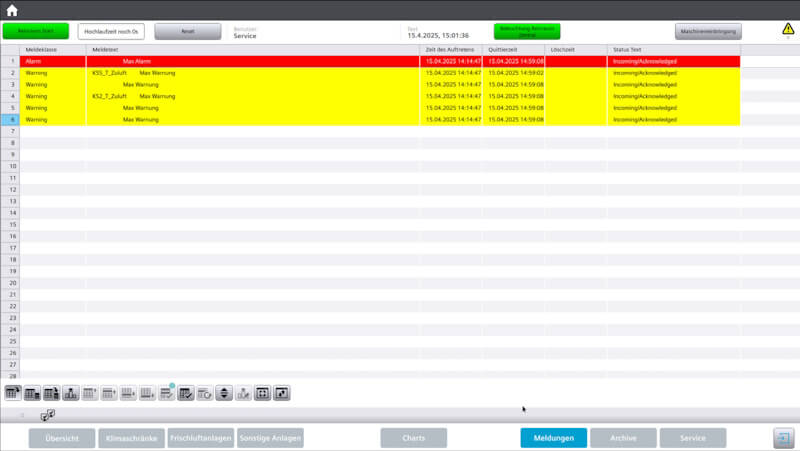

Back in February, we reported on our decision to operate the FFUs in a demanding automation project not via one of our control units for EC fans, but rather via a powerful combination of a Siemens S7-OpenController and decentralized ET200 peripheral modules. The intuitive operation and visualization are achieved through a generous 21-inch WinCC Unified Panel, which clearly displays all relevant processes. In addition to classic process visualization, the system also offers comprehensive archiving of measured values and user logins. This creates transparency and traceability – crucial factors in modern production environments.

Another focus was on the integration of an FMS system via OPC-UA. This open, standardized interface enables seamless and vendor-independent communication with higher-level systems. The time synchronization of all components is reliably performed via a customer-provided NTP server, ensuring a consistent database. In the area of room air conditioning, a sophisticated solution with a total of 80 FFUs (Fan Filter Units) is used. These are distributed across three RS485 communication lines and controlled via the EBM Papst Modbus protocol for precise room pressure regulation.

For return air conditioning, five air conditioning units are used, complemented by two fresh air systems, which are specifically used to control the plenum pressure. Additionally, a control system for two airlocks was implemented to ensure controlled access and maintain constant pressure conditions. The system is rounded off by an intelligent lighting control system that not only increases energy efficiency but also ease of use. All the technology is housed in high-quality control cabinets that are optimally designed for the system's requirements.

2025-04-16

Category:

PLC / automation

Date:

2025-04-16

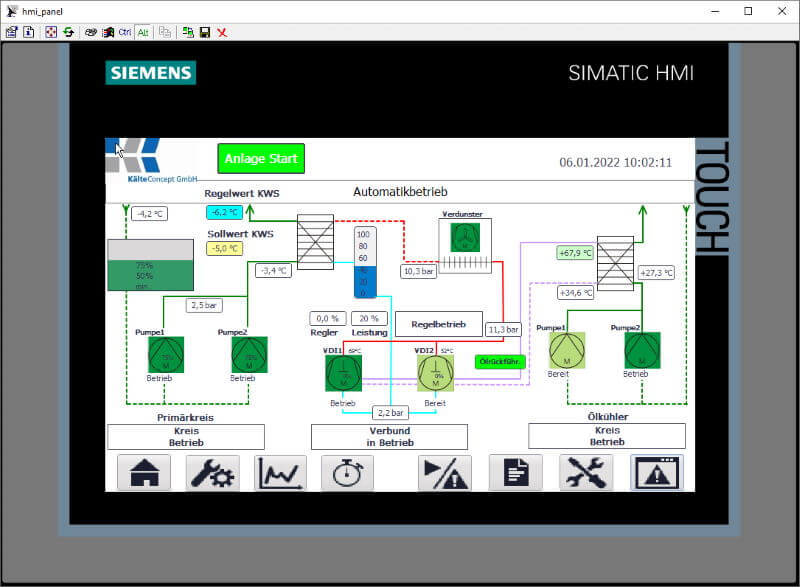

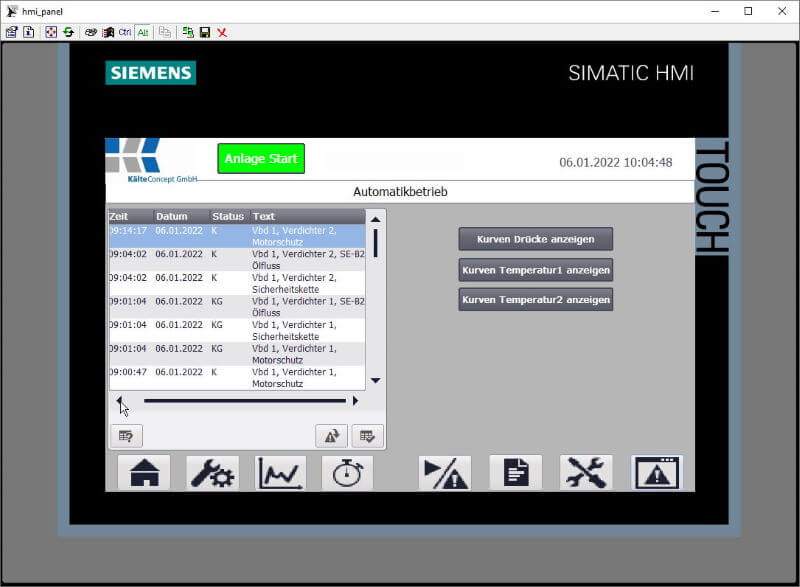

Automation of a Refrigeration System by SIEMENS SPS S7

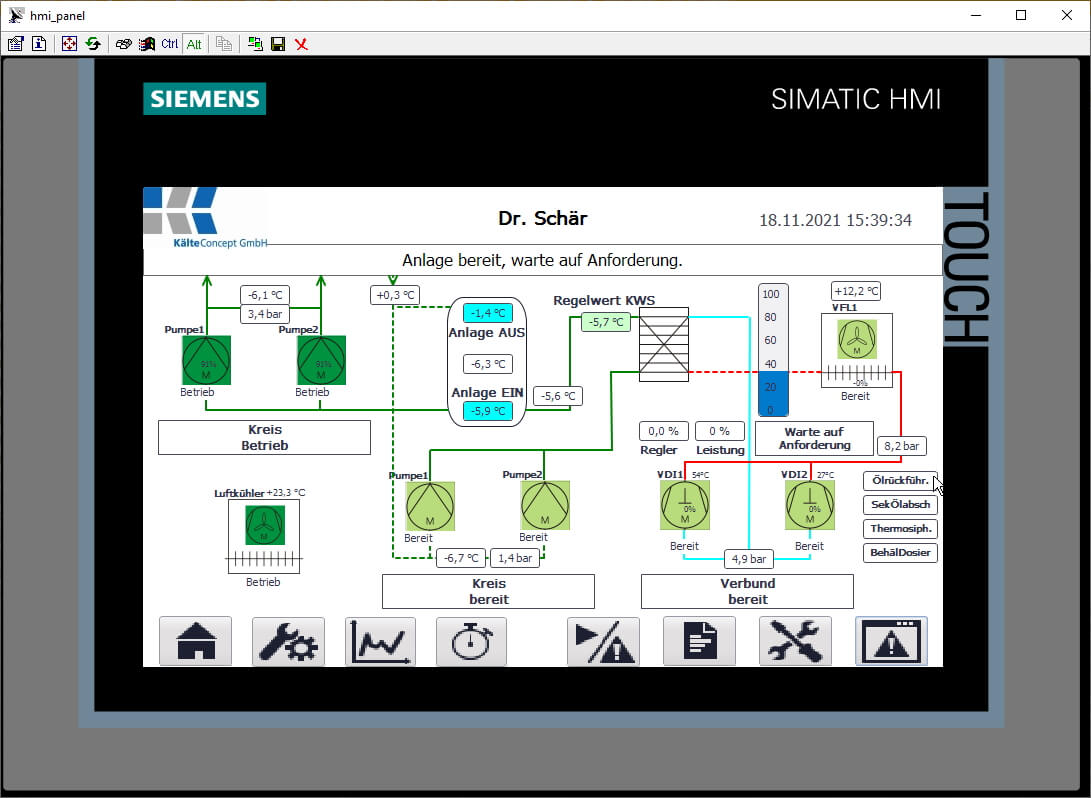

Around 1900 breweries were often set in the underground a plant of chestnut trees for cooling on top. True or not, this is what came to your author attention while watching a TV-report about Carl von Linde. Today the chestnut groves will be used more often to sit here and enjoy the results of the brewing process, the cooling is business of technique. Last week we had the opportunity to support our partner KälteConcept in doing the whole automation at a refrigeration system.

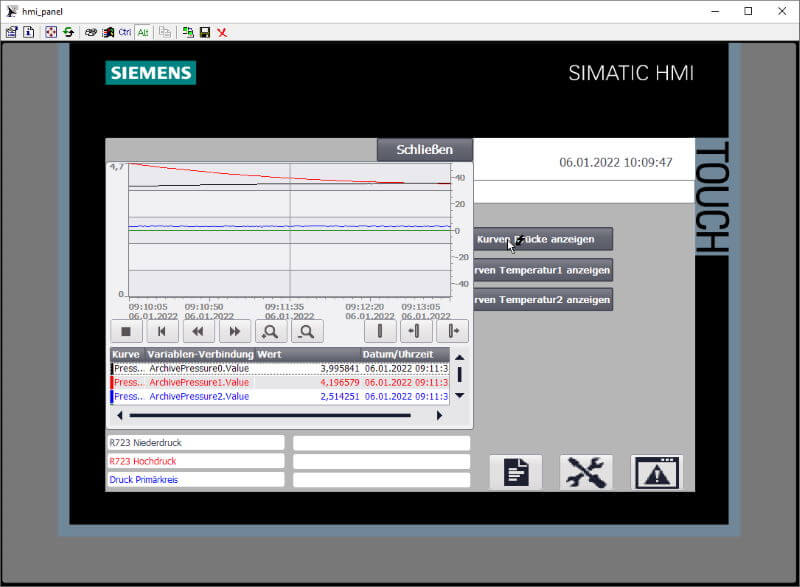

The core was a S7-1500 used as CPU, as HMI a KTP900 comfort is used. The cooling appliance consists of 2 screw compressors from Bitzer. The cold brine cycle was realised with 2 Magna pumps, controlled in close loop by pressure, while the 2 Grundfoss-pumps of the lubrication cycle were controlled alternating in redundancy for sake of a long operation life. The highlight of the automation is an error log, that saves all relevant pressures and temperature carts of the last 3 minutes BEFORE an error will have occurred.

2023-01-12

Category:

PLC / automation

Date:

2023-01-12

Control of a Water Chiller by SIEMENS SPS S7

More and more people suffer from intolerances to different ingredients of foods. Consequently mainly large bakeries creates special products and therewith a kind of normality for those people. For one of these larger bakeries we commissioned a NH3 cold water chiller together with our partner KälteConcept at the end of last year.

Of course we applied our proven rack controller for climate cascades. The core of the automation is Siemens S7-1500 using TP900 Comfort Panel as HMI controls 2 large centrifugal compressors of 75kW each. The total Refrigeration power is roundabout 420 kW. The most sophisticated item is the permanent archiving of the important operation values in a ring buffer. So in case of an error all process data of the last 30sec before the error occurred are available. In in case of a failure it makes the service work way easier.

2022-01-15

Category:

PLC / automation

Date:

2022-01-15

Remote Commissioning of a S7-Controll for a Cooling System

Due to the pending quarantine regulations in China that requires a couple of additional days if not weeks, we decided to go for a remote commissioning of a cooling system together with our partner Kälteconcept using Skype and Teamviewer.

The plant itself, a subcritical CO2 Fluid-cooling-appliance was in central china, used in a wind tunnel of a Chinese Automobile Company, is designed for up to 850 kW cooling power. It consists of 2 parallel compound lines with 3 CO2 compressors each, partially controlled by VFDs.

Practically it was done with Tia-Portal V15 on a S7-1500 CPU with a TP900 Comfort-panel. The special feature is a Pre-Error-Archiv was saves, in case of a fault, all relevant system data for the last 30s BEFORE the error occurred.

Finally it was a total success with only winners. The end user saved some money and was practically forced to an intensive training, we avoided a long commissioning trip with a unpleasant quarantine and finally the environment wins by avoiding flight traffic. A random view at the sky above our house compared to one on feb. 21rd in 2012 speaks for itself.

2021-06-18

Category:

PLC / automation

Date:

2021-06-18

Data link to Beckhoff-PLC via OPC-UA

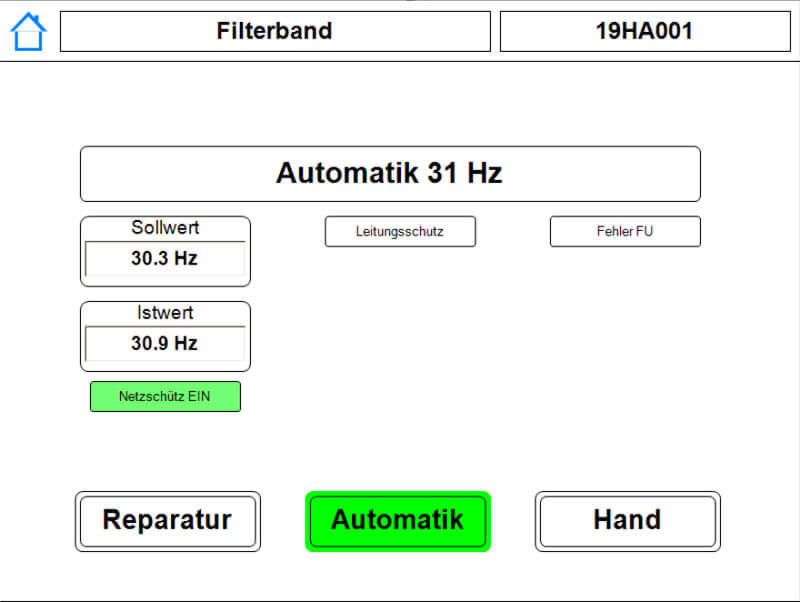

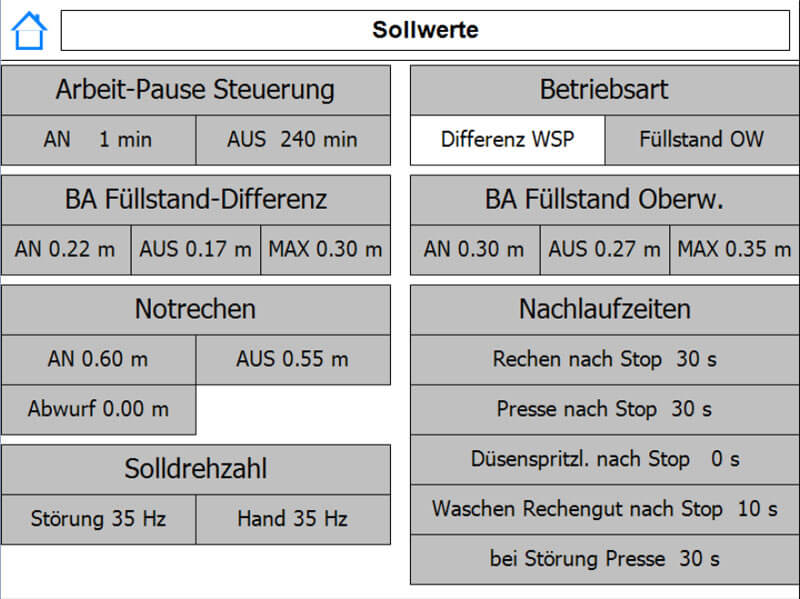

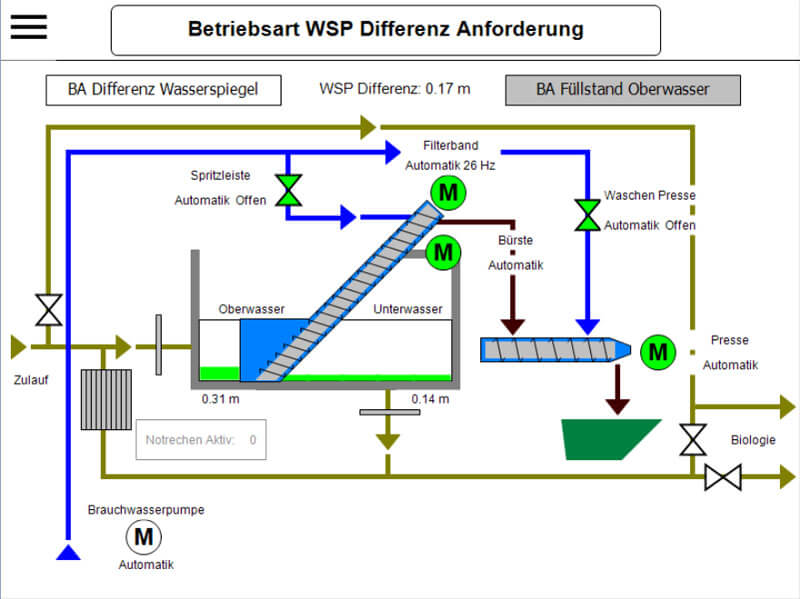

Our local water supply company is realising a new waste water handling appliance in a small town. The control of the rake bare is our task inside the complex structure.

Two different operation modes are possible; either the difference of water level in front and rear the rake or the level of waste water in front of the rake is used to control. The drive of the rake is controlled by frequency inverter. The measurement of the filling level is realised by 2 radar sensors.

There is a Beckhoff-PLC used as industrial PC with 12’’ touchscreen. The I/Os are integrated by Ethercat, the link to the FMS is done via OPC-UA. All this is programmed by TWINCat3.

2019-07-25

Category:

PLC / automation

Date:

2019-07-25

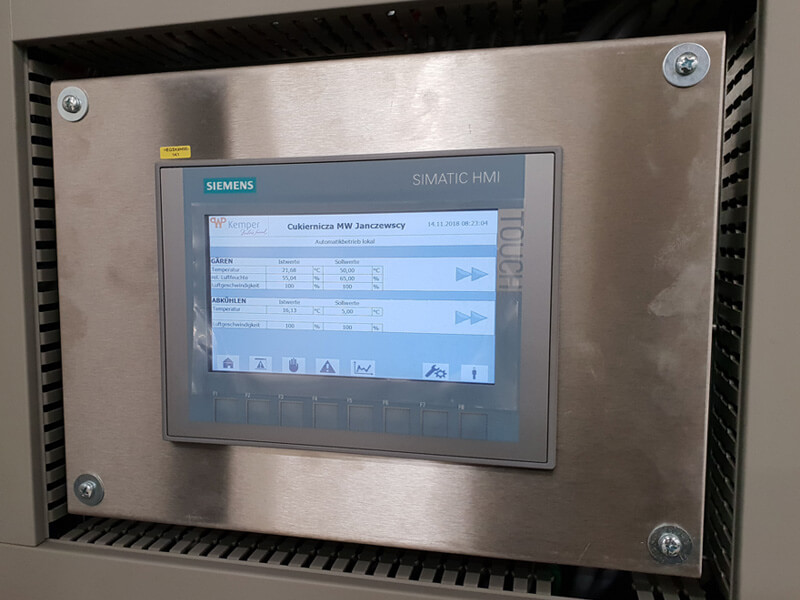

Control and Visualisation of Air Conditioning at SIEMENS SPS S7

Right in time for the Christmas Business and ordered by a big bakery supplier the control and the suitable visualisation of the Air Conditioning of a donut production line was passed to customer at the gates of Warsaw.

Realised on an S7-1500 programmed with TIA-portal it guarantees the air conditioning of 2 rooms, which could do both, proofing and resting.

2018-11-27

Category:

PLC / automation

Date:

2018-11-27

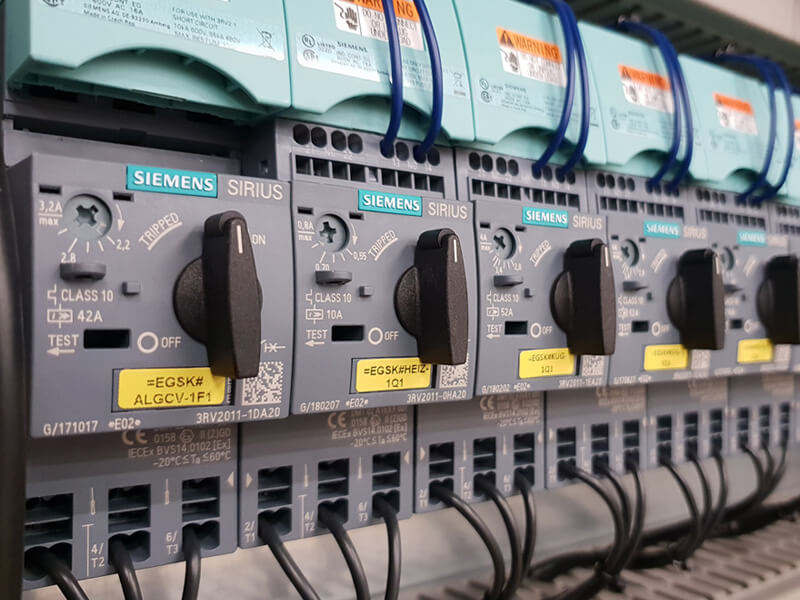

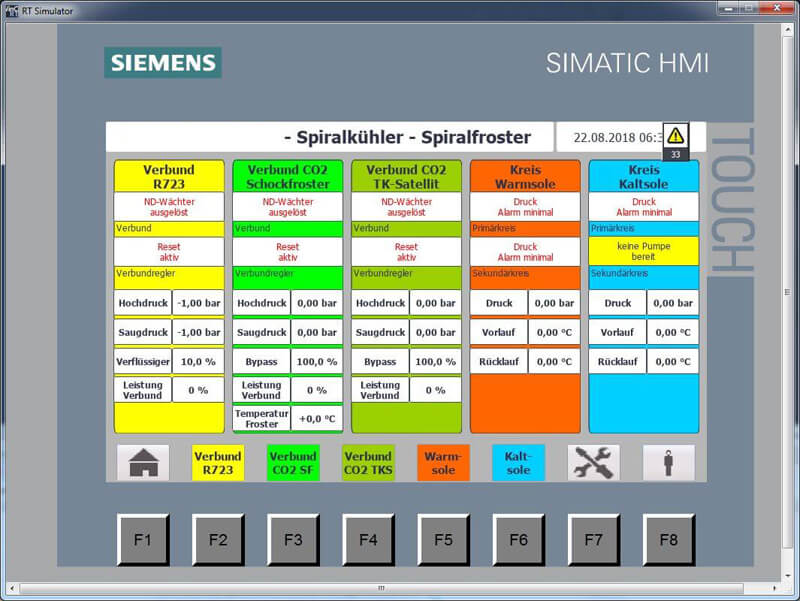

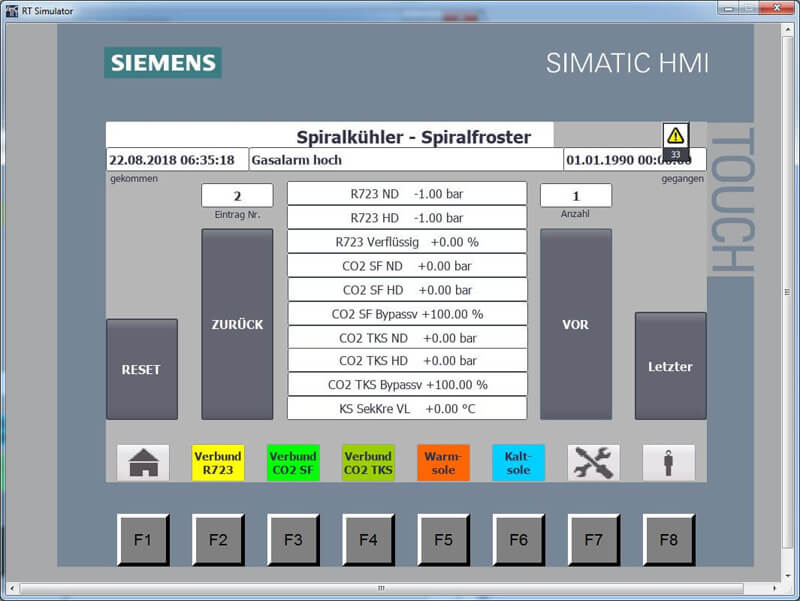

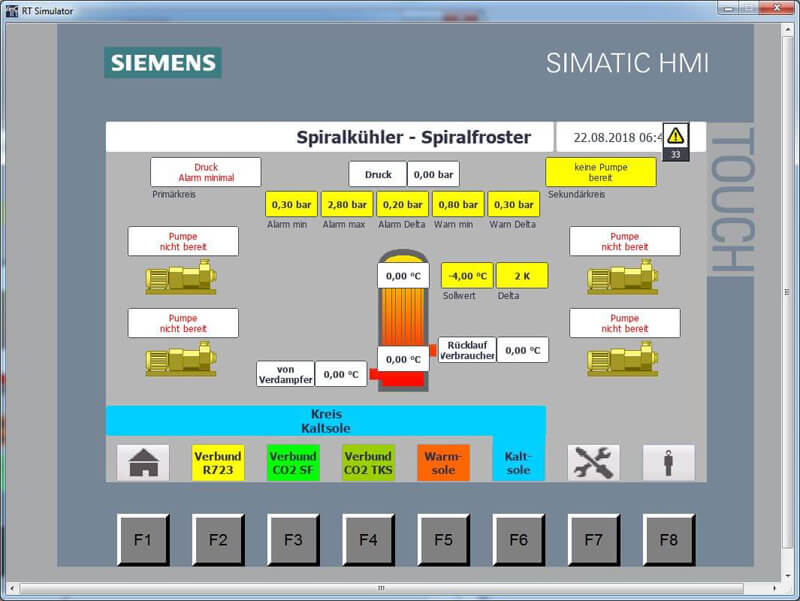

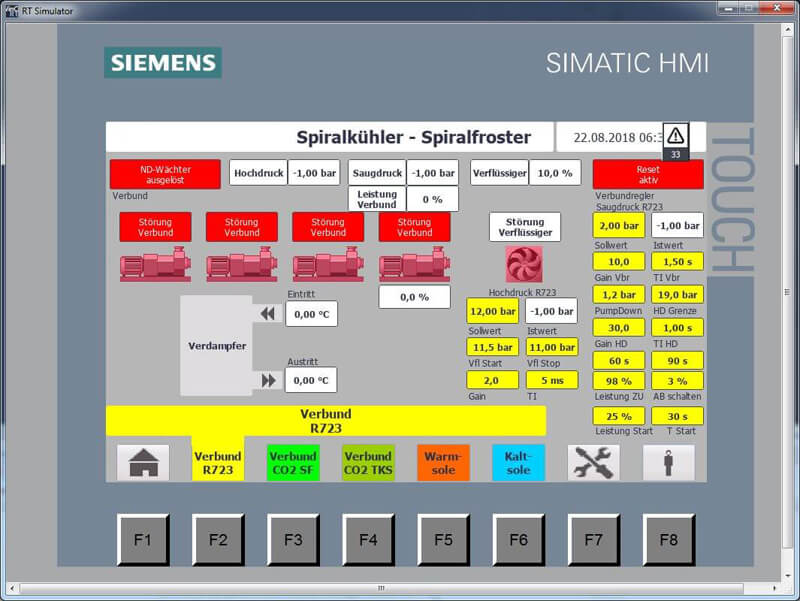

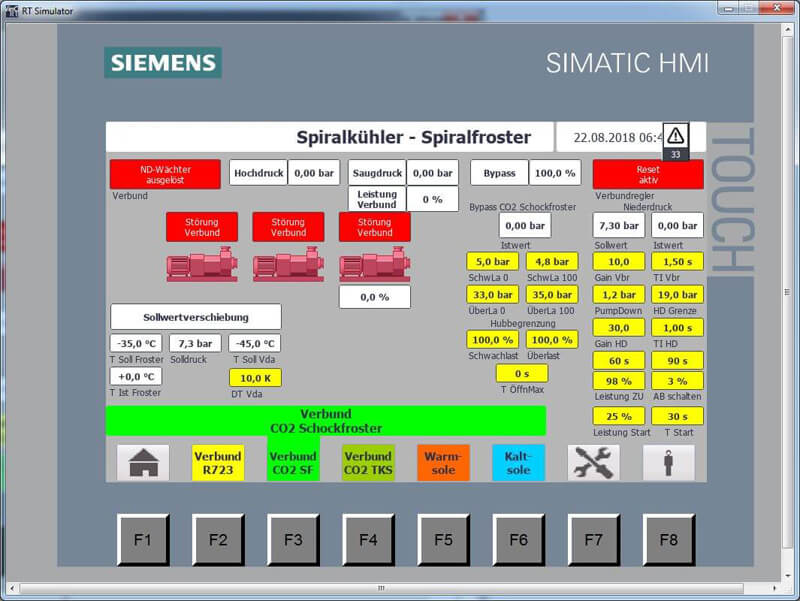

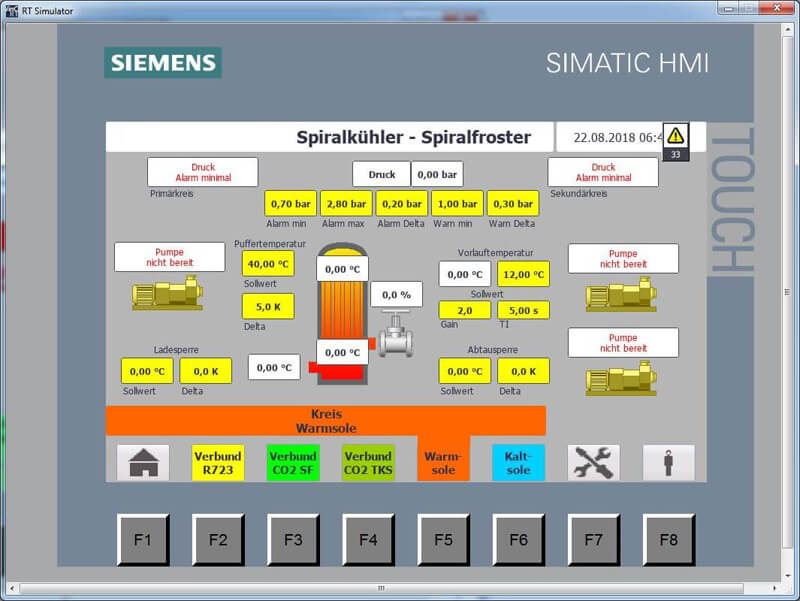

Compressor Racks for Blast Freezers

Together with our Partner KälteConceptwe finished a plant with several compressor racks for blast freezers, spiral cooling conveyors and frozen storages with cold and warm brine generation on a Siemens PLCS7-1500 CPU programmed with TIA-portal.

In total the plant consists of:

- - 4 R723 compressors, one controlled by Variable Frequency Drive (VFD) the other 3 compressors in a 2-step-control mode

- - 3 CO2 compressors for a blast freezer, one VFD-controlled

- - 1 compressor for frozen storage, VFD-controlled

- - defrosting, blast freezers and frozen storages with warm brine

- - 3 integrated rack controllers for demand oriented supply of the refrigerating capacity

- - demand oriented control of a R723 condenser

- - heat recovery for warm brine generation

- - controlled warm brine flow to reduce the thermal stress of the evaporator while defrosting

- - cold brine charge cycle with pump redundancy to compensate for different operation hours

2018-08-27

Category:

PLC / automation

Date:

2018-08-27

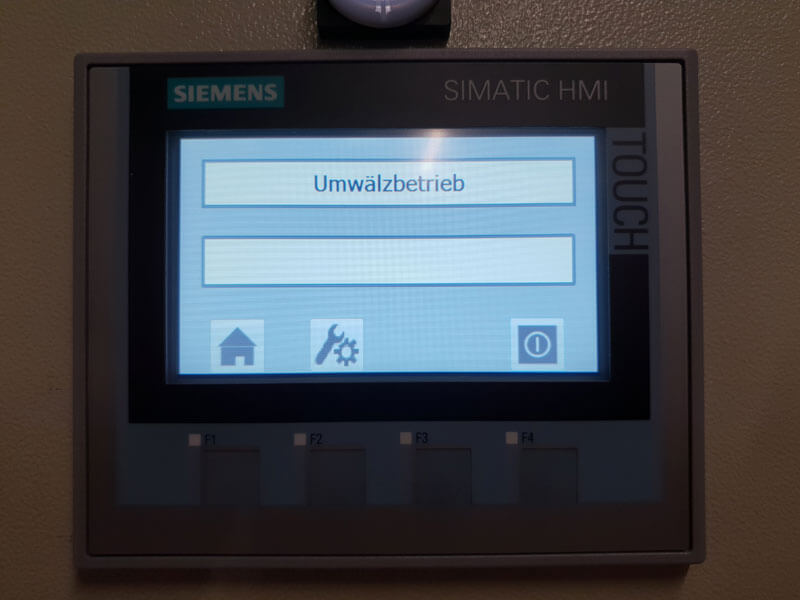

Replace a defective Siemens PLC of a swimming hall Automation

Corrosion and other environmental factors required the replacement of a S7-313 PLC and its OP7 operating interface by a S7-314 with a touch panel KTP 400 Comfort done by our PLC technicians in the following steps.

2018-05-29

Category:

PLC / automation

Date:

2018-05-29

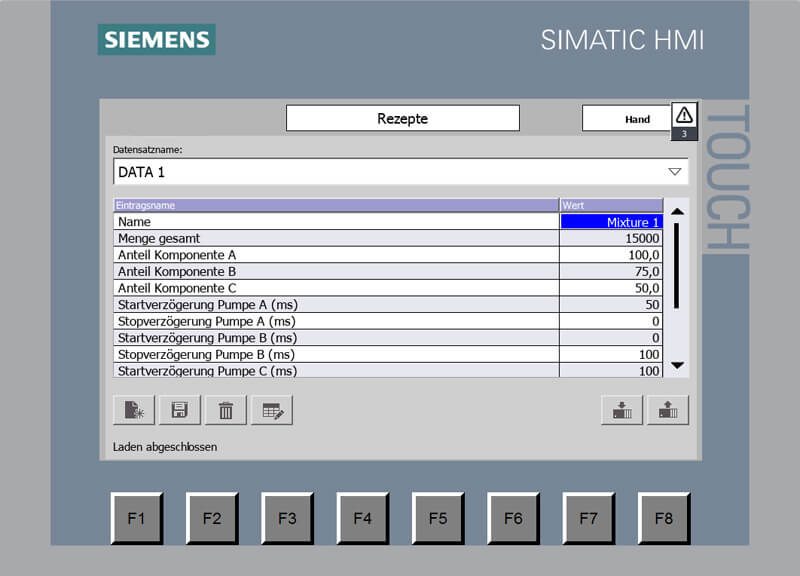

Batching Plant for Polyurethane

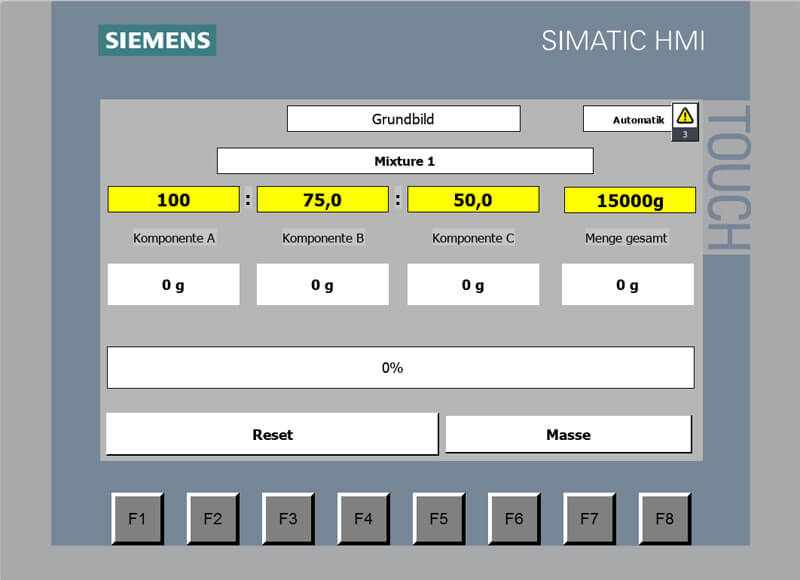

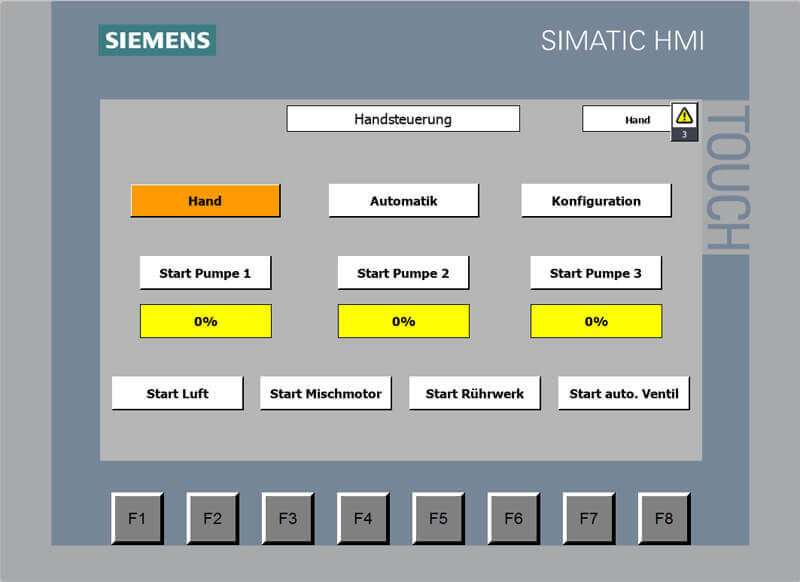

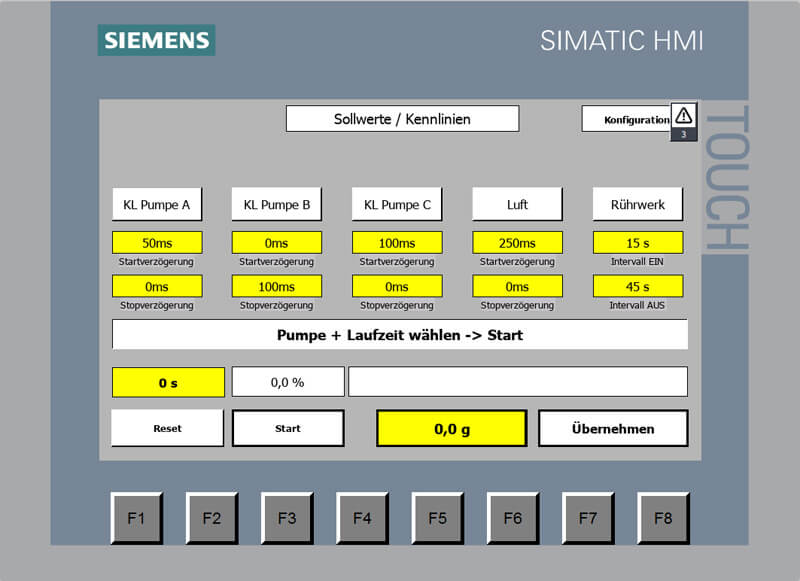

The latest PLC project of vbk technology is a batching plant with 2 or 3 components for Polyurethane.

Therefor a new SIEMENS S7-1200 CPU is applied with different LCD Touch panels.

- The special features of the project are:

- - recording of the pump duty line, that requires no additional sensor for the volume measurement

- - choose able operation mode - either installation stops after achieved setting or endless discharge

- - program is configurable for 2 or 3 components, therewith less maintenance efforts achieved

2018-03-16

Category:

PLC / automation

Date:

2018-03-16

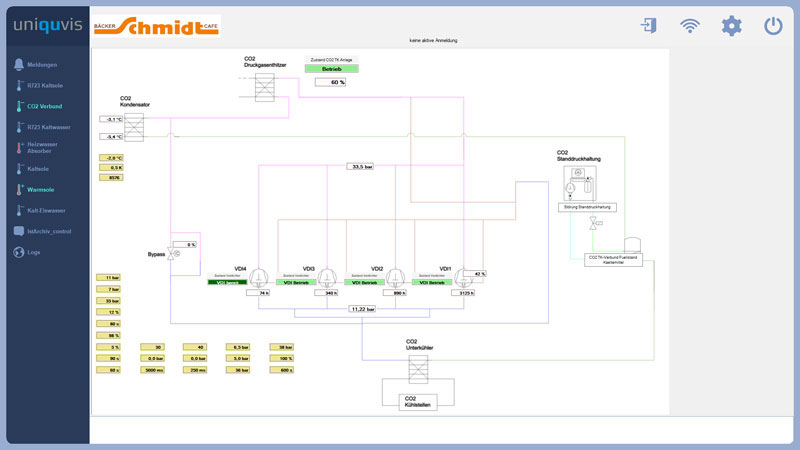

HVAC Visualization - uniquvis

Right in time for the pre-christmas-seasonKälteConcepthanded over a newHVAC-plantto Bäckerei Schmidt.

As for the costumer interface the process visualizationuniquvisis on duty and delivers all data costumer required in a perfect manner.

2017-12-14

Category:

PLC / automation

Date:

2017-12-14

"Power & Free" conveyor system on a SIEMENS PLC S7-1200

A „Power & Free“ conveyor system of a hand painting equipment for a big manufacturer of windows and doors is the latest highlight of vbk technology automation products. 13 stoppers that need to be free configurable, the control of a traction chain drive as well the automatic suction are made for the operation by a touch panel.

An especially designed functional module allows simple scalability for the present application as well as for upcoming projects. Currently this functional module is used to set minimum dwell time and maximum number of traverses per stopper by the customer.

The program is done on SIEMENS PLC S7-1200 via TIA-Portal V14.

2017-04-06

Category:

PLC / automation

Date:

2017-04-06

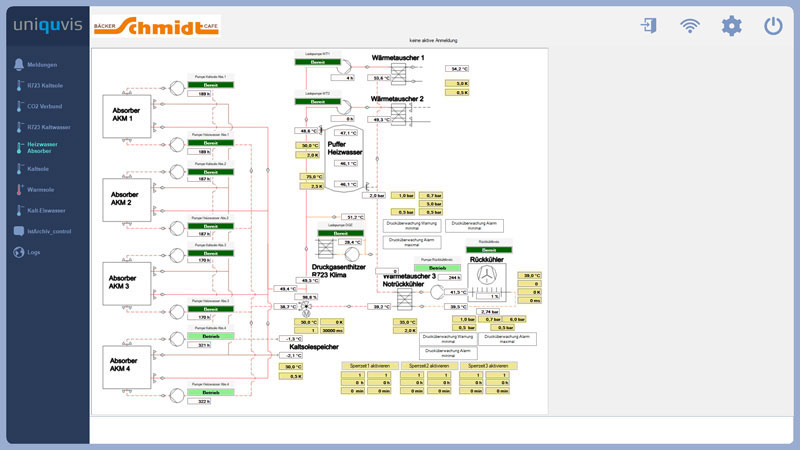

HVAC Visualization - uniquvis

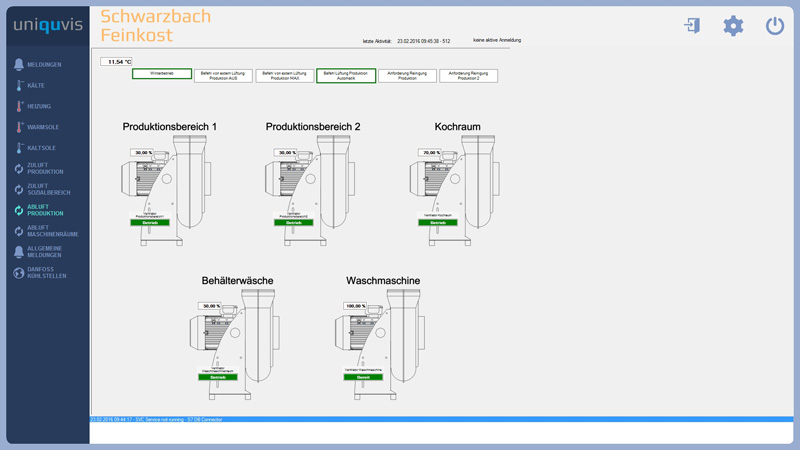

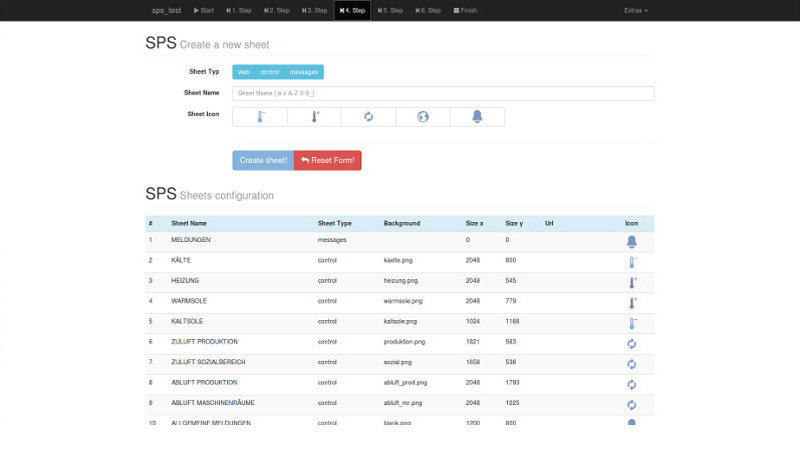

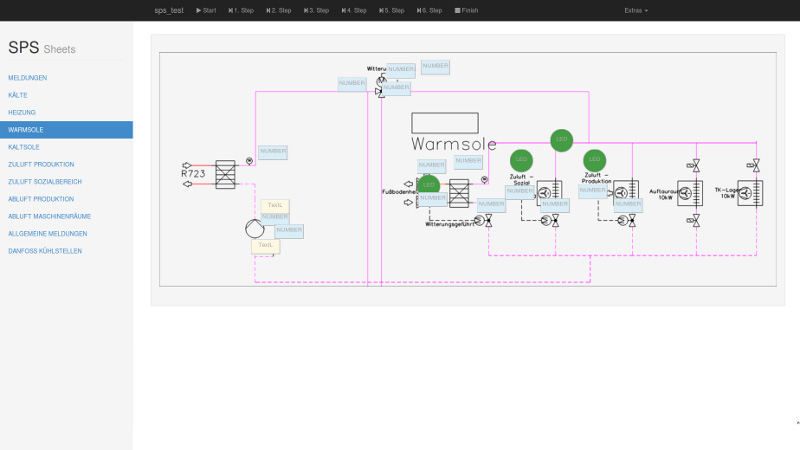

After completion of the HVAC-plantwith our partner KälteConcept at Schwarzbach Feinkost GmbH end of 2015, we now handed over the access at an IT-level to our very interested client. With the uniquvis systems the heating - ventilation - air conditioning plant is fully visualized.

A MySQL database with more than 20 tables provides all data for the visualization. An HTML5 application, which could be accessed by each modern browser, is used for configuration and operation of the visualization.

2016-02-23

Category:

PLC / automation

Date:

2016-02-23

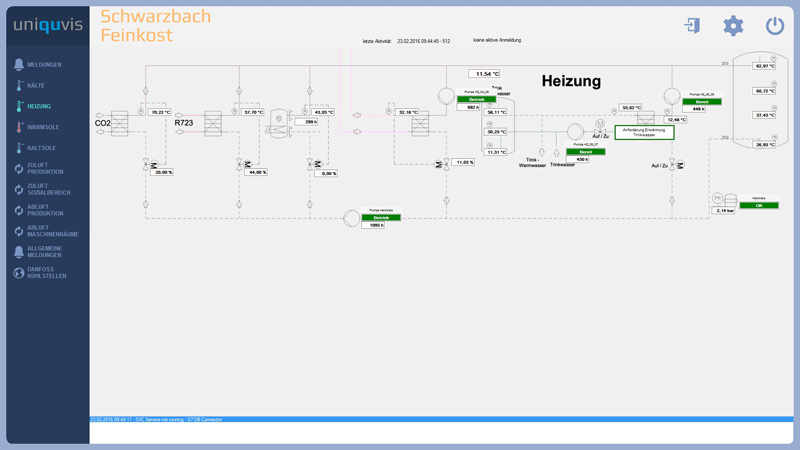

Control and Visualization of HVAC plant

Having realized the main control of a few smaller refrigeration plants bySPS-S7 for our partnerKälteConcept over the year 2015, we are now proud of having been able to contribute to the reopening of the Schwarzbach Feinkost GmbH. With an extraordinary level of heat recovery, we realized an overall concept of heating, ventilation and air conditioning (HVAC) in record time, to allow the owner to deliver their products to their markets.

In addition to switchboard design, SPS-programmingand the commissioning, a special highlight is awaiting our engineers - the visualization of the whole HVAC plant.

2015-11-30

Category:

PLC / automation

Date:

2015-11-30