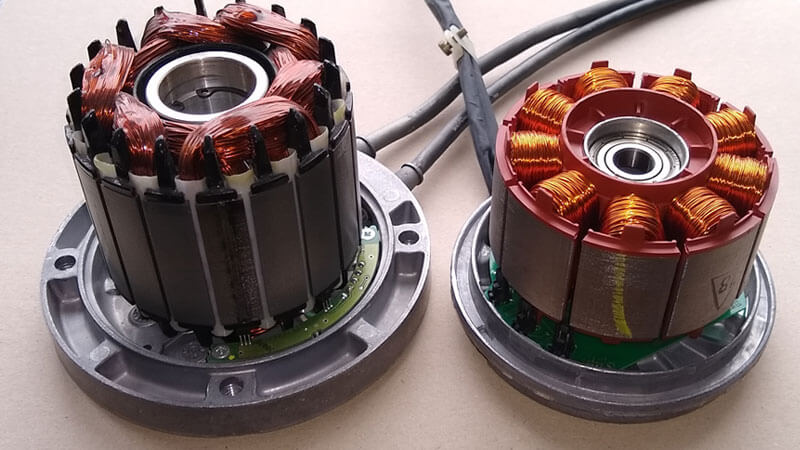

EC Motors – often without Temperature Sensors inside

Also this year your author supports the Sächsische Kältefachschule at their education in different graduation levels. The chosen topics content again electrical drives mainly EC-drives.

A constantly recurring question is, why do so many EC-motors do not have any temperature sensor inside as – no matter if a simple clixon-contact, a PTC or even a PT100 – most induction motors do have. The answer lies in the functionality in combination with its needed direct combination with a control drive. Sometimes unconscious you consider an application inside an EC-fan. In this combination of EC-motor, Control-Drive and an impeller it succeeds that with a fixed combination of motor with impeller, combined with a simple limitation of running speed the motor can be protected by overheating as long as the medium temperature of the moved air is not improper high.

2022-04-08

Category:

General

Date:

2022-04-08

EC Motor Control – Parameter Variance against Bottlenecks

By the end of the last year a US-American OEM-customer placed a bigger order for controllers for their EC fans. He is going to proceed by controlling their EC-FFUs with our EC-control devices. The biggest possible variety of different data sets for all EC-fan suppliers (ebm papst, Nicotra Gebhardt, Ziehl Abegg, Rosenberg) was more than welcomed. Obviously they are preparing themselves to avoid any bottlenecks when it comes to some postponements at different EC-motor manufacturers. We appreciate to support.

2022-02-04

Category:

General

Date:

2022-02-04

Control of a Water Chiller by SIEMENS SPS S7

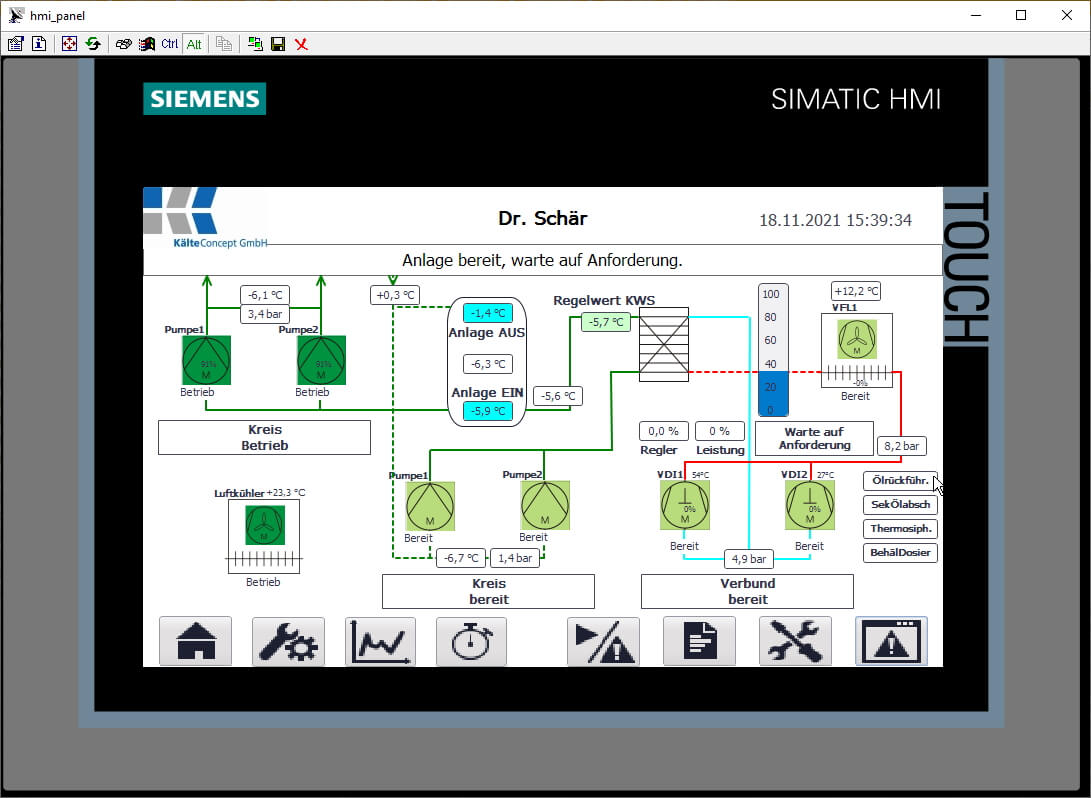

More and more people suffer from intolerances to different ingredients of foods. Consequently mainly large bakeries creates special products and therewith a kind of normality for those people. For one of these larger bakeries we commissioned a NH3 cold water chiller together with our partner KälteConcept at the end of last year.

Of course we applied our proven rack controller for climate cascades. The core of the automation is Siemens S7-1500 using TP900 Comfort Panel as HMI controls 2 large centrifugal compressors of 75kW each. The total Refrigeration power is roundabout 420 kW. The most sophisticated item is the permanent archiving of the important operation values in a ring buffer. So in case of an error all process data of the last 30sec before the error occurred are available. In in case of a failure it makes the service work way easier.

2022-01-15

Category:

PLC / automation

Date:

2022-01-15

Maintenance of a FFU Plant

It speaks for the process equipment if you do not take note about it. After almost 10 years trouble free operation of a FFU-plant with EC-fans from Nicotra||Gebhardt the owner decided to let someone check whether if anything is fine or not. As the FFU Server is not linked to the Internet and the whole system including Inline-I/O-station as well as the old OPC-DA link are still in fine operation and no intentions to use some virtual solutions for the FFU-Control exist, we feel confident to state ‘currently no changes recommended, probably a slightly higher maintenance frequency is not a bad idea’.

Almost traditionally trips to the technology hot spot in Jena are scheduled by train. The way home at the lower train way creates unbelievable joy.

2021-11-19

Category:

General

Date:

2021-11-19

Automation of a FFU Plant

In week 41 the commissioning of our largest single 2021-project took place. From now on a FFU-Server including 4 structural layers is controlling up to 2.000 FFUs. Therewith our design- und programming efforts have been concluded worthy. Due to the size of the plant and its geometrical distances from the central FFU-Server to the EC-FFUs the communication to the 6 Gateway was realized by individual fibre links. Inside the FFU-Server an OPC-UA Server is integrated. It allows access to all data points, of each FFU individually, group wise or by structures along a customer FSM.

Due to the order volume and for the general importance the order had highest priority. Consequently we accomplished our tasks on the Server in advance of the commissioning close to perfection. Therewith we had enough time to support the customer by the communication checks and address-building works on site. Therefor once more two EC-fan control devices from our house has been used.

2021-10-27

Category:

General

Date:

2021-10-27

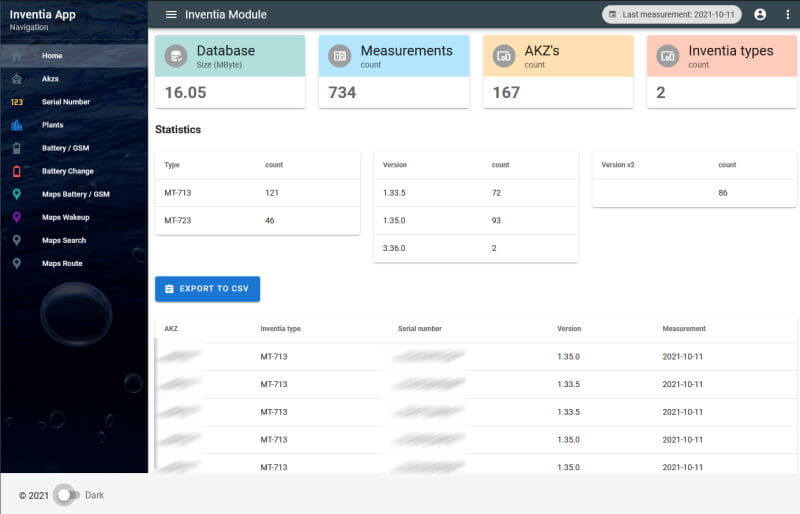

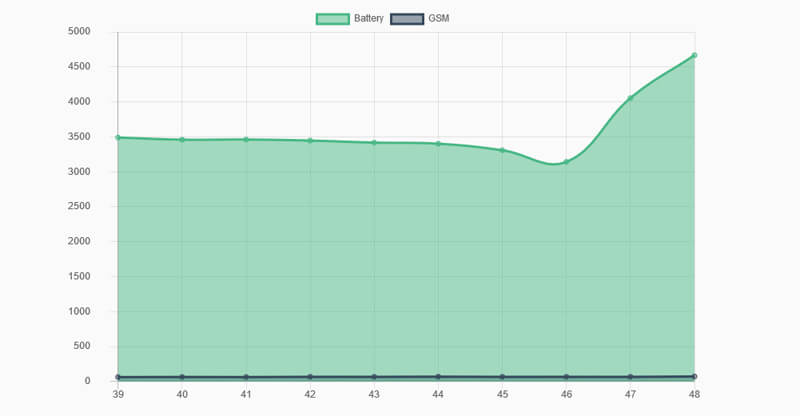

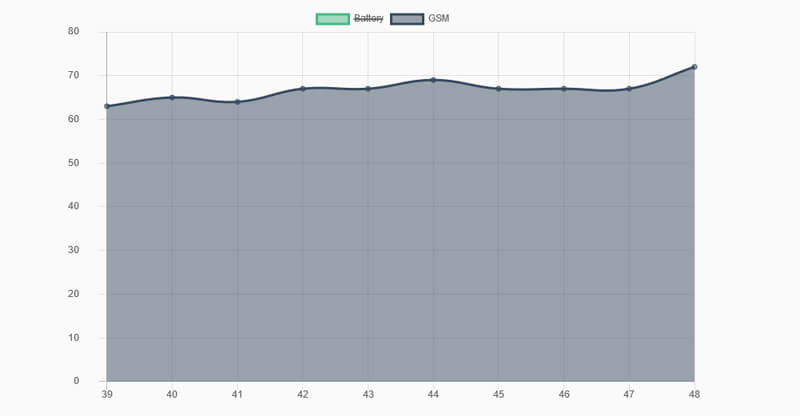

2 Years Monitoring of Telemetry Modules of a Water Supplier

For more than 2 years we have been observing a telemetry network applied at a fresh water pipe network of our local water supplier.

Our system is running full automatically and supplies reports to our customer that includes the battery charge levels of the applied modules.

The Frontend is designed as modern Single Page App that runs at each modern browser. It shows battery charge levels, battery changing intervals and the GSM-signal. Furthermore all values can be prepared graphically and shown as time chart.

The Backend is using a data base server that shows more than 100.000 entries already. Consequently the relevant values can be observed automatically and errors be seen. The battery charge states of the data log devices are separated to 3 levels what helps to optimize service trips, saves driving time and consequently costumer’s money.

2021-10-06

Category:

Programming / DB

Date:

2021-10-06