Cleanroom-Supplier from Taiwan visits Vogtland

Since more than 10 years General Ventitech Co. Ltd. has been our partner in Taiwan. No matter if support while building FFU-servers for cleanroom applications or the adaption of older EE-fans to latest control networks, or even the normal hardware business of control devices for EC-fans, it has become way more than business, it’s friendship.

CEO Schilling Yu (2nd from the left) and staff members at vbk technology

2024-04-26

Category:

General

Date:

2024-04-26

FFU Control without JAVA

Since round about 3 years the FFU-Server of one of our biggest cleanroom customers has been running on a virtual basis. The actual FFU-Server runs as service, but the graphical-user-interface (GUI) at java-based Internet Explorer. While the server part was more or less permanently improved over the years and utterly accepted by our customers, the GUI caused more and more complains. That part was using Internet Explorer based on JAVA-scripts. Sometimes MS edge took simple over the command and suppressed the old JAVA-GUI.

As the actual FFU-Server-core does not care about its GUI, the scheduler or the Inline I/O interacting and even the total OPC-Control by an overlaid FMS are still in charge, some customers even did not take note about the “deactivated” GUI, but it’s not nice, anyhow. Since a few months there is a solution for this. By a small program all functions of the GUI are presented in any Browser no matter if Edge, Chrome or Firefox. So our customers expect no more surprises if they are going to check the FFU-control.

2023-11-21

Category:

General

Date:

2023-11-21

uniqunet® - Trademark

From now on the trademark uniqunet is registered under file number 30 2023 008 408.1.

2023-10-19

Category:

General

Date:

2023-10-19

FFU-Control ebmpapst Modbus 5.0.1 lite

Normally the commissioning of “smaller” cleanrooms with our EC-control devices runs smoothly, that even completely new customers are able to manage this with a bit telephone support no matter if the FFUs uses ebmpapst-, NicotraGebhardt-, Rosenberg- or Ziehl Abegg-drives. But not so at a Biotec enduser in northern Germany end of January. Unfortunately more than one single issue existed that causes some trouble. Firstly a wrong cable PIN of the RJ45 (green/white instead of orange/white) was used that NetA and NetB of the main backbone was no more a twisted pair. Furthermore due to whatever reason the Modbus communication was not that fast and swift as usual.

As beside of a very few revisions hatches the whole cleanroom was completely sealed the search for the root cause for the pretty sluggish communication was not found. Finally a proper termination (RT = 120 Ohm) at the end of the modbus-rtu-line of 400m length lead to better system response times that the customer was satisfied even if the technicians loves to understand such things completely.

2023-03-08

Category:

General

Date:

2023-03-08

EC-Control Device for Belgium

We assume that some of our EC-Control-Devices are already in action in Belgium, as ebmpapst drives a service point BeNeLux in the Netherlands. However the first direct order from Belgium was accomplished and delivered by today. Therewith our interactive customer map may get an update.

Interestingly to be mentioned that the chosen parameter set was exactly as one of our big customer is using, that is bearing parameters for Modbus-rtu systems of ebmpapst, Ziehl Abegg, NicotraGebhardt and Rosenberg. If all of these different EC-fans are really used by our new customer may keep his secret.

2023-02-10

Category:

General

Date:

2023-02-10

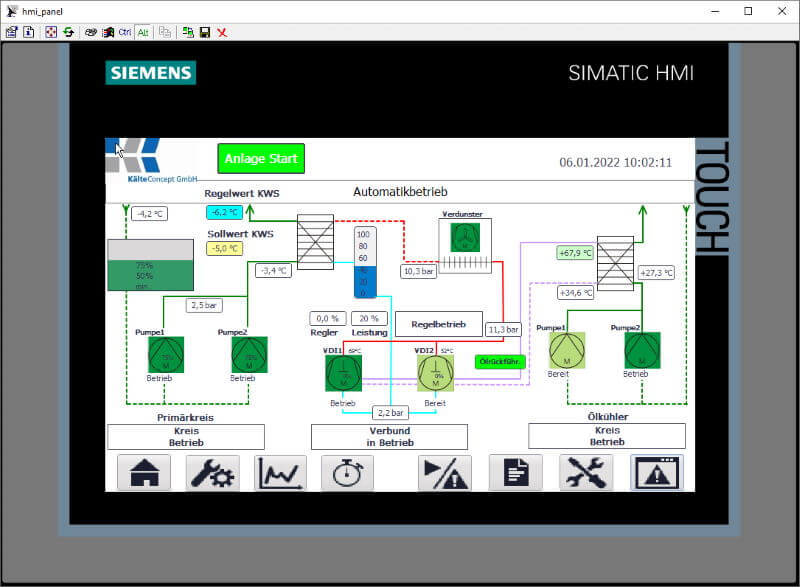

Automation of a Refrigeration System by SIEMENS SPS S7

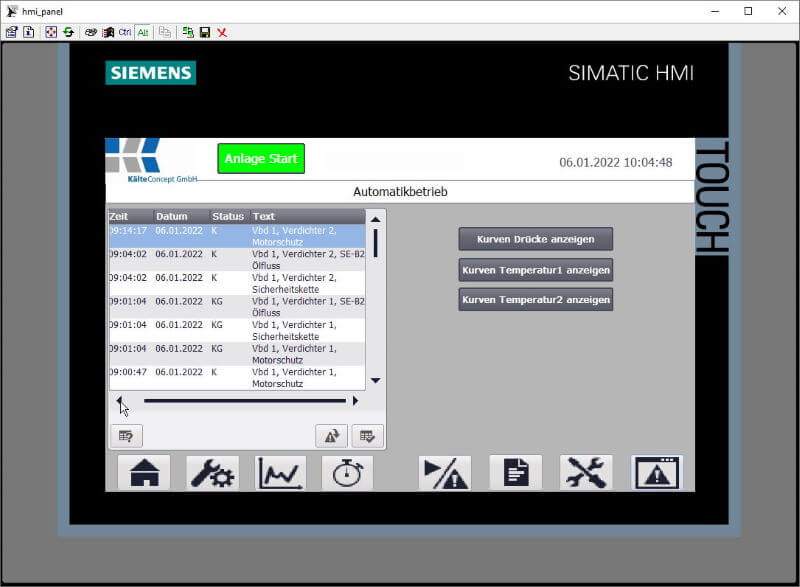

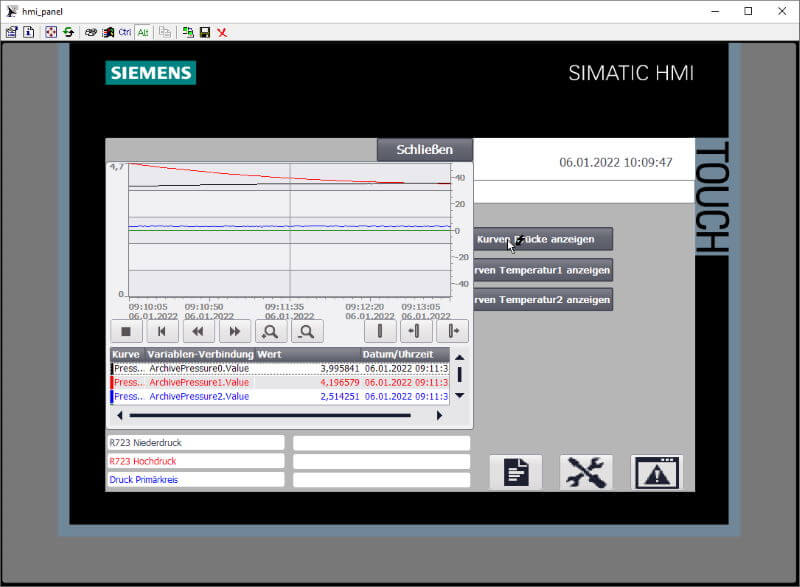

Around 1900 breweries were often set in the underground a plant of chestnut trees for cooling on top. True or not, this is what came to your author attention while watching a TV-report about Carl von Linde. Today the chestnut groves will be used more often to sit here and enjoy the results of the brewing process, the cooling is business of technique. Last week we had the opportunity to support our partner KälteConcept in doing the whole automation at a refrigeration system.

The core was a S7-1500 used as CPU, as HMI a KTP900 comfort is used. The cooling appliance consists of 2 screw compressors from Bitzer. The cold brine cycle was realised with 2 Magna pumps, controlled in close loop by pressure, while the 2 Grundfoss-pumps of the lubrication cycle were controlled alternating in redundancy for sake of a long operation life. The highlight of the automation is an error log, that saves all relevant pressures and temperature carts of the last 3 minutes BEFORE an error will have occurred.

2023-01-12

Category:

PLC / automation

Date:

2023-01-12