Belt control of a cooling tower using SIEMENS ET200

In keeping with the warmer temperatures, the control system for a refrigeration unit was on the agenda at the beginning of January. No, this time it wasn't a combined controller for our long-term partner KälteConcept, but rather the control of a belt drive for a cooling tower, including overdrive and a cleaning mode.

The entire system is implemented on a Siemens S7 ET200 PLC. The core component, and simultaneously the challenge, was the indirect control of the belt speed without the belt becoming too taut or tilting under load.

2026-01-28

Category:

PLC / automation

Date:

2026-01-28

Extension of a FFU Control Centre

A major Swiss semiconductor manufacturer, whose core business is components for HVDC substations, wanted to carry out an expansion of its production capacity shortly before the holidays. The new cleanroom included more than two dozen new EC FFUs. Our task was to extend the existing FFU control system from Nicotra|Gebhardt by adding a new structure and integrating the new FFUs. Since this was not the first expansion, everyone involved knew what mattered, so all FFUs communicated correctly right from the start and no corrective work in the field was required. That’s exactly how you want it to be.

The time that had been planned for commissioning could therefore be used for an in-depth log analysis of all control computers. In addition, the customer also had an issue involving EC motor impellers from ebm-papst. Here, Modbus FFUs were to be pre-parameterized for use in another area. Setpoint sources and addresses had to be adjusted accordingly. Fortunately, our universal control units are capable of doing that as well. The customer was certainly delighted with the straightforward support provided on this other part of the system.

2025-12-18

Category:

General

Date:

2025-12-18

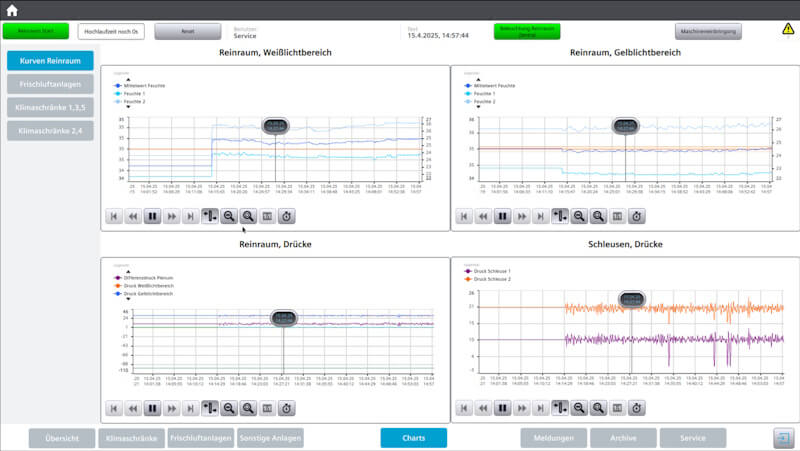

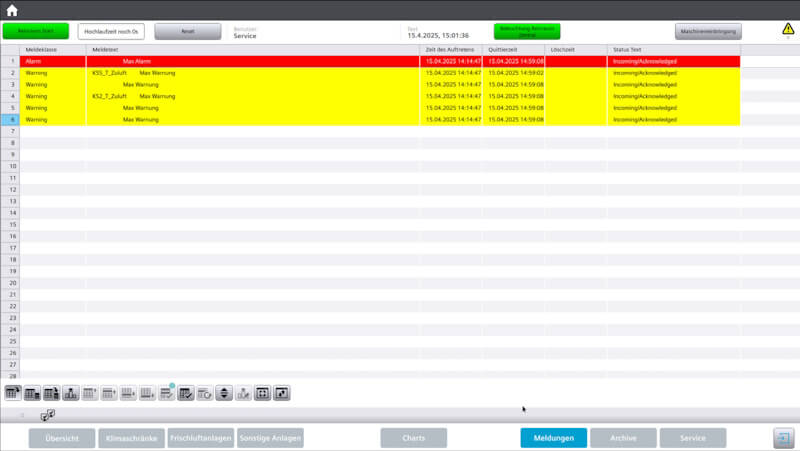

Cleanroom Automation with Siemens S7-OpenController and ET200

Back in February, we reported on our decision to operate the FFUs in a demanding automation project not via one of our control units for EC fans, but rather via a powerful combination of a Siemens S7-OpenController and decentralized ET200 peripheral modules. The intuitive operation and visualization are achieved through a generous 21-inch WinCC Unified Panel, which clearly displays all relevant processes. In addition to classic process visualization, the system also offers comprehensive archiving of measured values and user logins. This creates transparency and traceability – crucial factors in modern production environments.

Another focus was on the integration of an FMS system via OPC-UA. This open, standardized interface enables seamless and vendor-independent communication with higher-level systems. The time synchronization of all components is reliably performed via a customer-provided NTP server, ensuring a consistent database. In the area of room air conditioning, a sophisticated solution with a total of 80 FFUs (Fan Filter Units) is used. These are distributed across three RS485 communication lines and controlled via the EBM Papst Modbus protocol for precise room pressure regulation.

For return air conditioning, five air conditioning units are used, complemented by two fresh air systems, which are specifically used to control the plenum pressure. Additionally, a control system for two airlocks was implemented to ensure controlled access and maintain constant pressure conditions. The system is rounded off by an intelligent lighting control system that not only increases energy efficiency but also ease of use. All the technology is housed in high-quality control cabinets that are optimally designed for the system's requirements.

2025-04-16

Category:

PLC / automation

Date:

2025-04-16

FFU-Controll with SIEMENS PLC

For many years, EC fans have been operated with control devices from vbk technology, in many applications all over the world. But there are also those where the FFUs should be an integral part of the data network and therefore there is a desire for direct control by the PLC.

For an automation company from Nuremberg, EC-FFUs should now be connected to a SIMATIC ET 200 via their multi-fieldbus. The EC drives for this come from ebmpapst and are equipped with a Modbus rtu interface with identification D (5.01 Lite).

2025-02-12

Category:

General

Date:

2025-02-12

Extension of a FFU Plant

3 ago we reported of the accomplishment of a larger FFU-Plant in Eastern Europe. Almost 2000 EC-FFUs with proprietary RS485-Interface have been running since then without any issue.

As the costumer sent us the FFU-Server for the job, we took to opportunity to do a complete system update. From now on the GUI is running no more java based, but on different web browsers.

2024-10-29

Category:

General

Date:

2024-10-29

Power-OFF at FFU Plants

Following the last maintenance of a FFU-plant, voltage OFF/ON tests cycles caused that the EC fans from Nicotra||Gebhardt no longer reached their speed setpoints in a certain time, so that at several EC-drives speed control errors occurred. This kind of self-monitoring serves to ensure product safety so that units with a possible defect, such as a blocked impeller, do not keep trying to reach the set speed and switch themselves off.

The operator of the plant was once again advised with the following hints: “If cyclic OFF/ON tests are absolutely necessary, the FFU power circuits may be excluded. If this is not possible, the FFUs should be stopped before acting. This can be done either from the GLT or from the FFU-server.”

Since neither heavy tools nor spare parts were needed for the appointment, the climate-friendly train journey was a good choice.

2024-05-04

Category:

General

Date:

2024-05-04